Several commonly used UV screen printing processes combined with offset printing

Screen printing stands out in printing due to its thick ink layer, bright colors, and strong modernity. Additionally, UV screen printing uses ink with a solid content of 10%

Screen printing stands out in printing due to its thick ink layer, bright colors, and strong modernity. However, UV screen printing uses ink with a solid content of 100%, which eliminates component evaporation. After curing, the ink film thickness remains basically unchanged, making it advantageous to obtain thicker ink films. The printing and curing processes are easy to control, avoiding problems such as clogging and spots, and reducing downtime

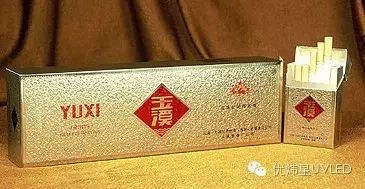

Choosing UV screen printing is more important because it fully expresses the perfect visual effects that UV technology can achieve, especially the special inks such as UV matte, ice flower, foam, wrinkles, refraction, gemstones, etc. in UV ink. By using screen printing technology to print them on the surface of a substrate with a metallic mirror luster, after being treated by UV curing equipment, a unique visual effect can be produced, appearing elegant, solemn, and luxurious. Therefore, UV screen printing products are mainly used for packaging printing of high-end, exquisite and unique cigarettes, alcohol, cosmetics, health products, food, drugs, etc

1、 Application of UV Partial Highlighting in Screen Printing

This is the most widely used combination of screen printing and offset printing, commonly used for book covers or back covers, brochure covers, product catalogs and introductions, product manual covers, product advertising brochures, posters, packaging soft and hard boxes or craft boxes, and so on

UV local gloss oil is a high gloss UV transparent oil that is used to print UV gloss oil on certain emphasized text and patterns on matte offset printing parts using a screen to create a contrast between local brightness and dullness on the surface, resulting in a richer and more aesthetically pleasing effect on the printed product. Many times, when a matte film is applied to the printed product and then UV local highlights are screen printed, the contrast effect of matte brightness becomes more pronounced

2、 Application of UV embossed oil in screen printing

As the name suggests, UV convex oil is a type of UV light oil with extremely high solid content. It is printed on offset printing parts through thick film screen printing. In addition to the brightness of UV light oil, its unique convex feeling can also enhance the visual effect of some physical photos. If processed and applied properly, it can achieve good visual effects and improve the three-dimensional and layered sense of physical patterns

3、 Application of screen printing UV ice flower (i.e. wrinkles)

Screen printing UV ice flower, also known as wrinkle ink, is a specially formulated UV varnish used for screen printing on offset printing parts. After UV initiation, UV curing, and secondary UV irradiation, the surface of the UV varnish produces a visual effect resembling ice flower, resulting in a wrinkled texture. The original UV large crack effect also evolved from this effect, with larger and rougher cracks appearing. The application of UV ice flowers is also very wide. Generally, their texture is more effective on large areas of color blocks. Of course, when using a single layout, it is possible to design a mixture of large area color blocks and small area patterns, which can better reflect the dynamic and varied effects. For example, when applied to gold and silver cardstock, the effect is more prominent

4、 Application of UV Matte in Screen Printing

UV matte screen printing is also a widely used effect, and the matte effect is more prominent on gold and silver cardboards with good offset printing. Visually, it is a semi matte sandy effect, which is divided into three types: fine sand, medium sand, and coarse sand. If used well, the effect is very good

5、 The application of screen printing UV snowflakes

Screen printing UV snowflakes have been widely used in the past two to three years, especially for printing on the laser card color printing surface of high-end cigarette packs. Its surface is a completely matte and delicate texture, and the effect is also highlighted by screen printing UV snowflakes on glossy offset printing. Sometimes, when using screen printing UV snowflake technology on offset printed parts of plain laser cardboard or light column laser cardboard, the image will be more vivid

There are many special UV effects for screen printing, such as UV small foam, large foam, crystal diamond, iridescent convex oil, rainbow convex oil, water mist, refraction, gold sand, crystal cracks, etc. As long as the design and application are in place, not only will the grade of the printed product be improved, but unexpected visual effects will also be obtained. Moreover, sometimes on the surface of the same offset printing product, multiple screen printing processes are designed and applied simultaneously, and the cross application of laminating (bright film or matte film), hot stamping, embossing and other processes can achieve a beautiful effect on a packaging decoration printed product