Smart "Core", New Life | Integrating UVLED into Thousands of Industries and Businesses

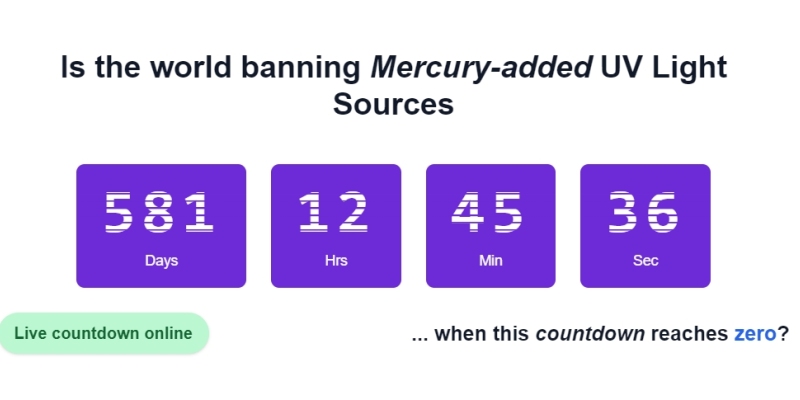

UV LED light source is more environmentally friendly, efficient, and energy-efficient compared to traditional UV mercury lamps. It is a truly sustainable green industrial technology that is widely used in many applications

Compared to traditional UV mercury lamps, it is more environmentally friendly, efficient, and energy-efficient, making it a truly sustainable green industrial technology that has gradually replaced traditional mercury lamp light sources in many application fields

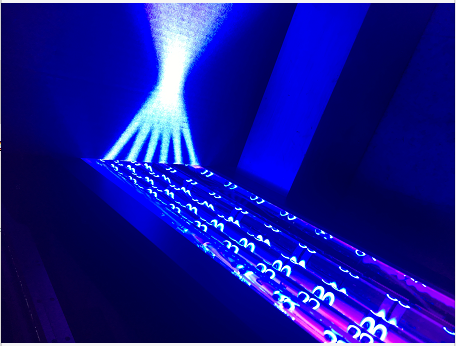

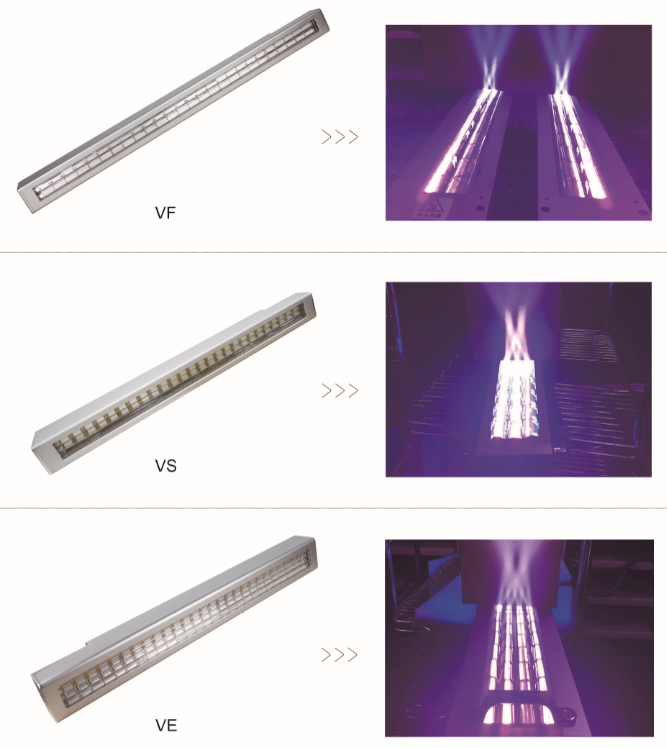

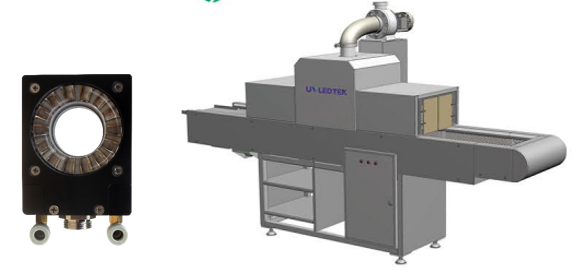

(Youweixing UV LED telephoto offset printing light source)

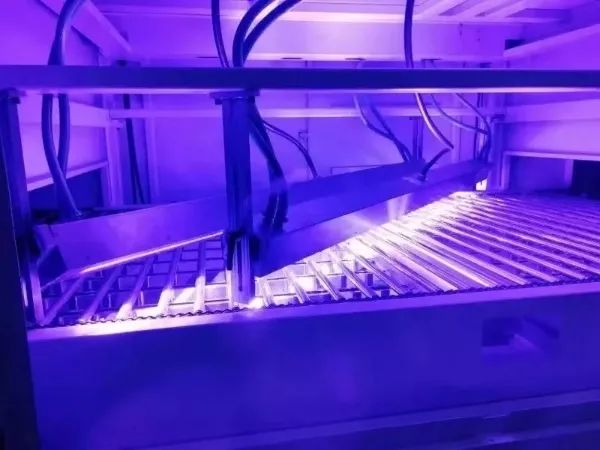

UV LEDs can directly convert electrical energy into UV light and emit single band ultraviolet light. The energy of the light is highly concentrated in a specific UV band, while traditional UV mercury lamps have a wide emission spectrum, with only a portion of the UV spectrum effectively curing, resulting in low photoelectric conversion efficiency and high energy consumption

Traditional mercury lamps generate infrared radiation and emit a large amount of heat, which can easily damage heat sensitive substrates. UV LED, as a cold light source, can effectively prevent the substrate from shrinking and deforming due to overheating, and has a wider adaptability to materials. At the same time, no ozone is generated during the curing process, which can maintain a good working environment and is safer and more environmentally friendly compared to traditional mercury lamps

UV LEDs do not require preheating like mercury lamps, nor do they need to keep the lamp tube constantly on to maintain its lifespan and work efficiency. UV LED can instantly turn on and off the light, and the output energy can be freely set and automatically adjusted according to the machine speed, which is very energy-saving and easy to control

The service life of UV LED lamps is more than 10 times that of traditional mercury lamps, and the light attenuation is very slow, and the service life is not affected by the number of switches. Almost no maintenance is required, reducing maintenance costs

The LED light source equipment has a small size, and the illumination device and related supporting devices are very compact. It does not require the large mechanical installation space and pipeline construction of the past, and can adapt to various production processes. The production process is also more efficient

Advantages of UV LED inkjet

Energy saving, efficient, high resolution, adaptableMultiple substrates

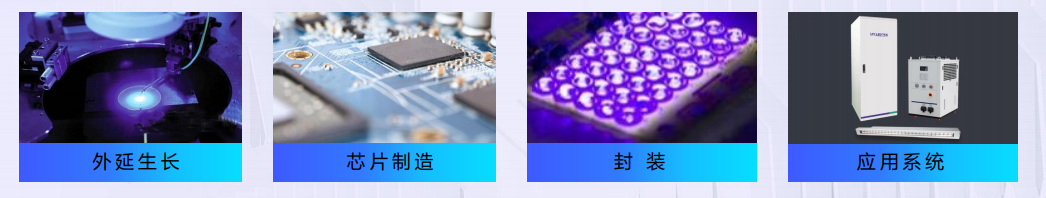

Application areas

Industrial or decorative printinglarge formatInkjet printing, label and packaging printing

Compared with ordinary UV printing, LED UV offset printing

Throughout the entire printing production process, it is more energy-efficient, environmentally friendly, and has a longer lifespan

Can reduceUp to 70-80%Energy consumption

And it has outstanding performance in printing materialsadaptability

Components (capacitors, inductors, various plugins, screws, chips, etc.)fixed

Moisture proof sealing, core circuit and chip protection, anti-oxidation coatingprotect

Circuit board shape preservation (corner)coating

Ground wire, flying wire, coil fixation

Wave soldering through-holeMASK

Compared to traditional painting methods

UV LED won't workMoisture content of substrateinfluence

And fromSealed bottom, primer, color correction, topcoat

Comprehensive construction technology for rapid curing of UV LED

Eliminating traditional wooden substrates and topcoatsLong dryDrying and solidification time

andMulti channel spraying constructionThe complicated process

Can achieveMechanization of the entire lineAssembly line operation

For the factoryImprovement of production capacityHas greatPromoting effect

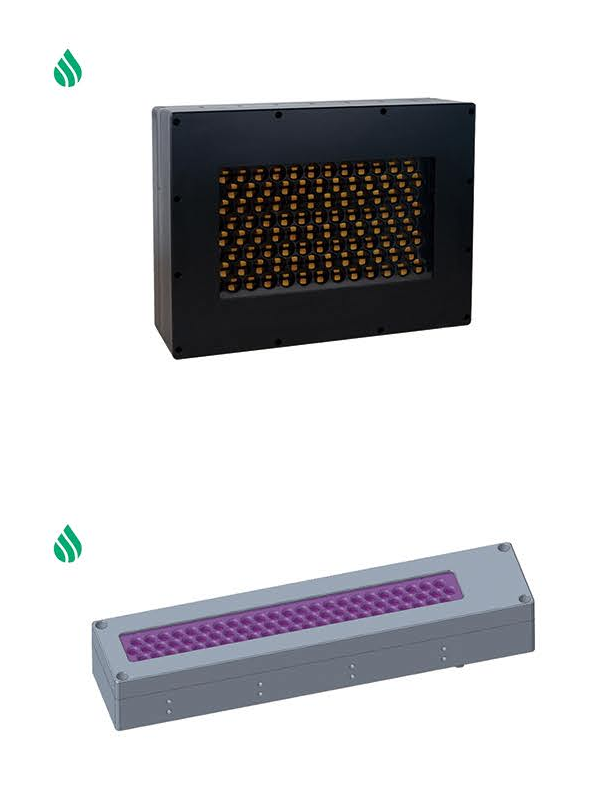

There are many advantages to using UV LED curing adhesive

for exampleLow heat releaseLower energy demand

Save curing time and locationImprove productivityIt's easierautomation

Therefore, it is widely usedMicroelectronics industryreachmedical equipmentIn the field

lead toAdhesive bonding, fixation, and protectionWaiting for action

Advantages of LED

Cold light source, low pollution, fast curing, low energy consumptionFilm-forming propertyCan be superior

Application areas

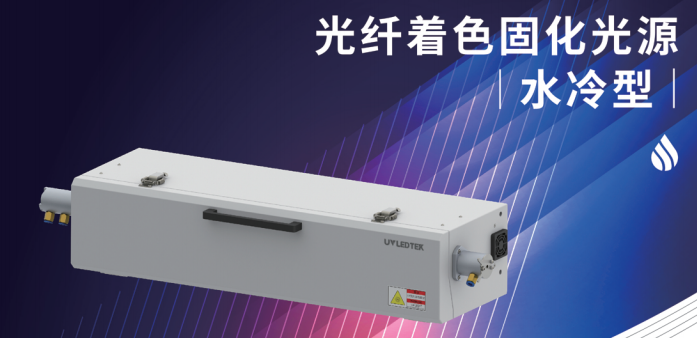

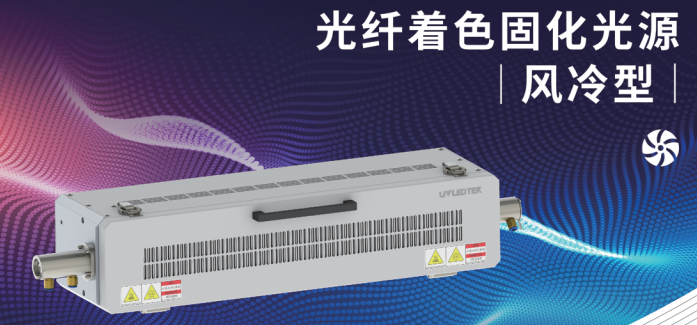

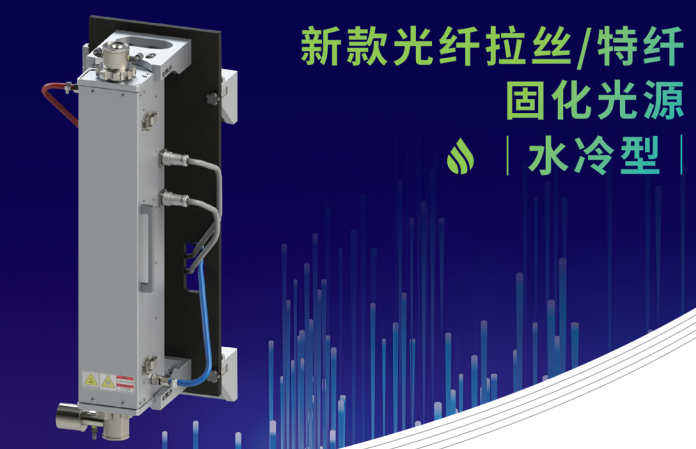

Mobile phones, automotive coatings, optical lenses, plastic coatingsoptical fibercoating

The active production and life have created a rich and colorful range of UVLED applications

Creating a New Life with "Chip" Intelligence

Attentive service, quality first

-March 2008-

- October 2015 -

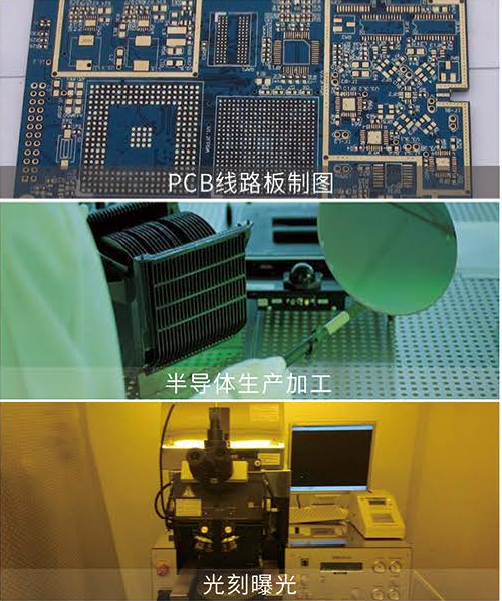

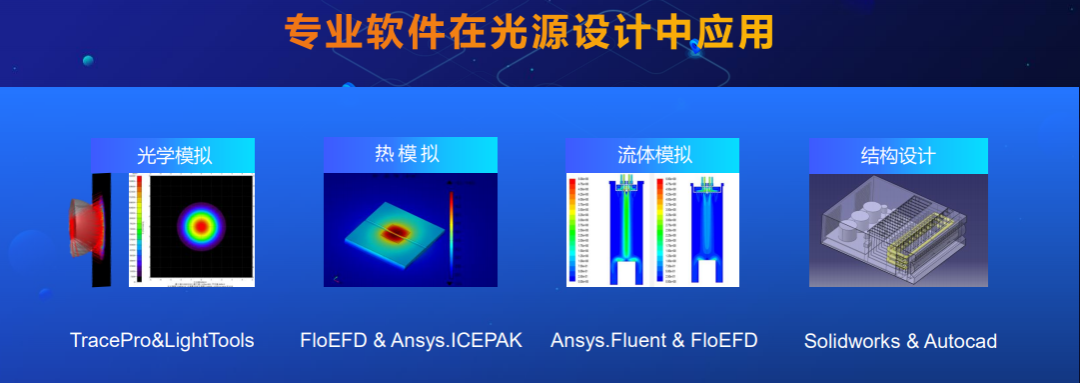

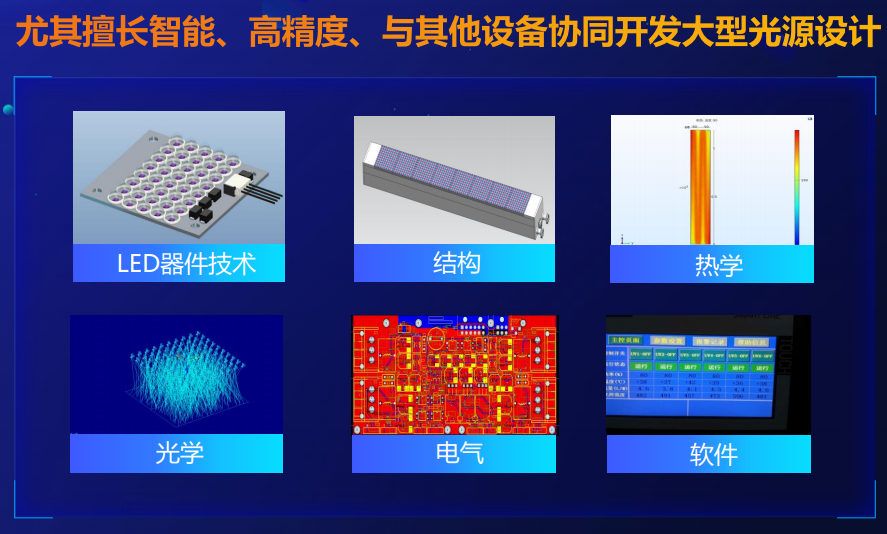

Youweixing has started to develop fiber optic, offset printing, label, and LCD curing light source systems, implementing the "Peak Plan" of research and development, and bravely climbing the high-precision and cutting-edge field of UV curing

Strategic cooperation has been established with leading domestic UV ink suppliers to promote offset printing light sources in bulk. As of July 2019, more than 110 units have been installedRanked No.1 in the domestic offset printing machine modification market share;

The successful installation of the company's first high-power LCD curing surface light source marks the successful entry of the company's products into the LCD cell stage process, which is the first of its kind in China

The Youweixing label flexographic curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, opening the door to cooperation with well-known brand label machine manufacturers

The market of UV label, offset printing, LCD and other light source systems of Youweixing has expanded to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, and its overseas performance has achieved rapid growth

Wuhan Youweixing Technology Co., Ltd

Address: 5th Floor, Building B, R&D Building 1, Modern Service Industry Base, Huagong Science and Technology Park, Donghu New Technology Development Zone, Wuhan City

Postal Code: 430223

Contact number: (+86) 027-87971689

Contact email: sales@uvledtek.com (Sales)