Semiconductor UVC LED UV sterilization technology

Technical working principle

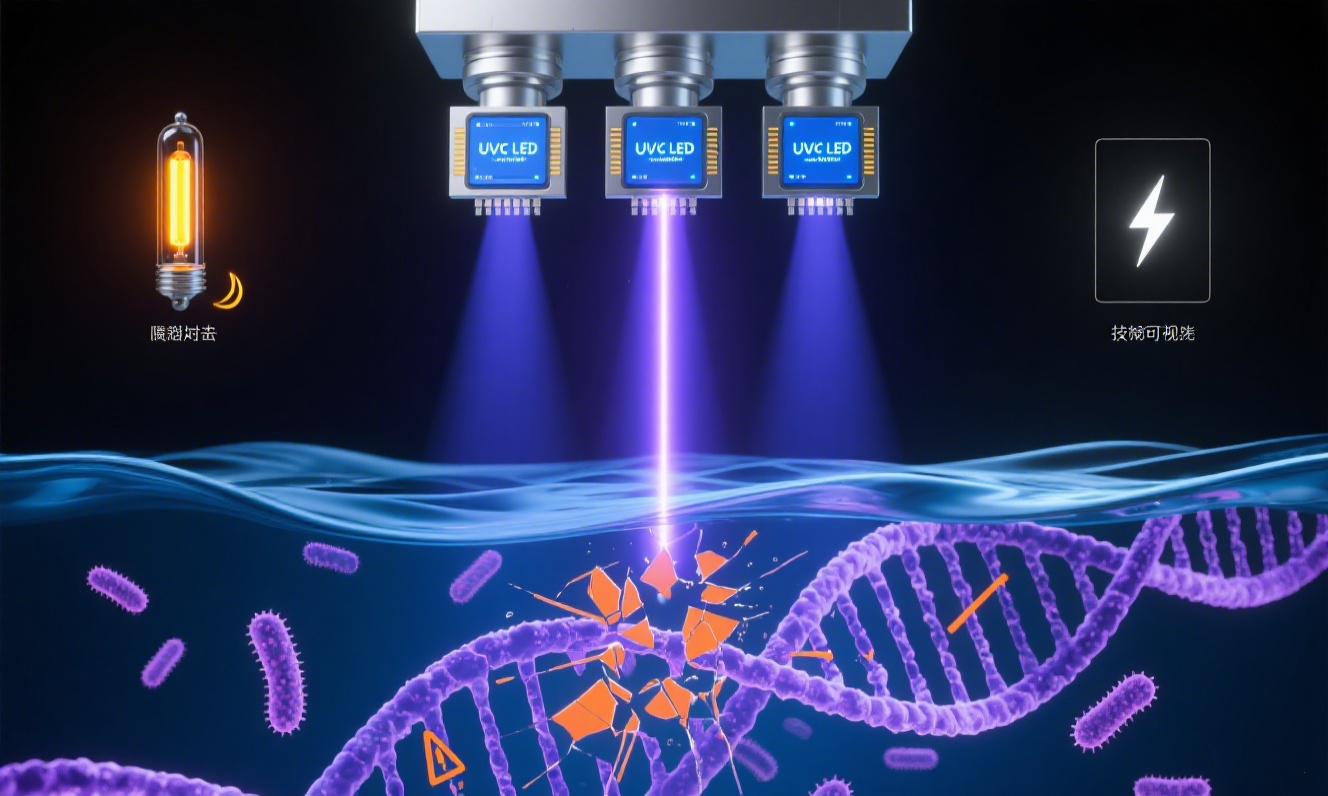

Understand the core working mechanism of semiconductor UVC LED light source sterilization technology, from light source excitation to microbial inactivation throughout the entire process

Light source excitation

When current passes through the semiconductor chip of solid-state UVC LED, the electrons and holes in the chip recombine, releasing energy and exciting the generation of ultraviolet light in the UVC band

ultraviolet radiation

The generated UVC ultraviolet radiation radiates into the surrounding space or water flow, with its wavelength precisely focused on the range with the strongest killing effect on microorganisms. It can penetrate the cell membrane of microorganisms and directly reach their internal genetic material

Destruction of genetic material

After being absorbed by microorganisms, UVC ultraviolet rays can damage the molecular structure of their DNA and RNA, preventing microorganisms from reproducing and achieving bactericidal effects

Sterilization completed

Under the continuous action of UVC LED light source, bacteria, viruses, fungi and other microorganisms in water, air or object surfaces quickly lose their activity, achieving the purpose of sterilization and disinfection

Working principle diagram

The semiconductor UVC LED light source sterilization technology uses precisely controlled semiconductor luminescence to generate specific wavelengths of ultraviolet light, efficiently killing various microorganisms. The entire process does not require chemical reagents, there is no secondary pollution, and it is a green and environmentally friendly disinfection and sterilization method

Advantages of semiconductor UVC LED light source sterilization technology

Compared to traditional ultraviolet sterilization technology, semiconductor UVC LED light source sterilization technology has outstanding advantages in multiple aspects

Efficient and fast

UVC LED light source can instantly reach the rated sterilization power without preheating, and can achieve efficient sterilization in a short period of time, which has significant advantages for scenes that require rapid processing

Safe and reliable

It does not contain harmful substances such as mercury, avoiding environmental pollution and safety hazards caused by the breakage of traditional mercury lamps. At the same time, its emitted ultraviolet light has a concentrated wavelength and is less likely to produce secondary pollutants such as ozone

Energy saving and durable

The energy consumption is only a part of traditional mercury lamps, which can effectively reduce energy consumption. Moreover, its service life can reach tens of thousands of hours, far longer than traditional mercury lamps, reducing replacement frequency and maintenance costs

Compact and flexible

The solid-state structure makes it compact in size, lightweight, and easy to integrate into various devices such as small water purifiers, portable sterilizers, air conditioning vents, etc., making it more suitable for a wider range of scenarios

Strong controllability

The output power and working time can be precisely controlled through circuit design, and adjusted according to different sterilization requirements to achieve precise sterilization and avoid energy waste

Comparison with traditional UV sterilization technology

| Comparison items | Traditional mercury lamp | Solid state UVC LED | advantage |

|---|---|---|---|

| Start Time | Need to preheat for 3-5 minutes | instant start | Solid state UVC LED |

| environmentally | Containing mercury, there is a risk of contamination if damaged | Mercury free, environmentally friendly and safe | Solid state UVC LED |

| service life | About 8000 hours | 10000+hours | Solid state UVC LED |

| Energy efficiency | High energy consumption and significant heat loss | Energy saving and efficient | Solid state UVC LED |

| volume weight | Large size, difficult integration | Compact and lightweight, easy to integrate | Solid state UVC LED |

Widely applicable scenarios

The semiconductor UVC LED light source sterilization technology can be applied in multiple fields, providing efficient and safe sterilization solutions for different scenarios

Water treatment field

Integrating UVC LED light sources in devices such as water purifiers, water dispensers, and smart faucets can perform secondary sterilization on filtered water, ensuring the safety of drinking water; In industrial wastewater treatment, it can also efficiently kill harmful microorganisms in water

Air purification field

Used for air purifiers, air conditioners and other equipment, it can quickly kill bacteria, viruses and other microorganisms in the air, purify indoor air, especially suitable for use in hospitals, offices, homes and other places

Surface sterilization field

Made into a portable sterilizer, it can sterilize and disinfect the surfaces of objects such as mobile phones, desktops, and tableware. It is easy and convenient to operate, meeting daily hygiene and protection needs

Medical and health field

Plays an important role in medical device disinfection, operating room air purification, and other aspects, effectively reducing the risk of cross infection and providing safety guarantees for the medical environment

Looking for a suitable UVC LED sterilization solution for you

We provide professional technical consultation and customized solutions to help you choose the most suitable semiconductor UVC LED light source sterilization products