Chasing China's' Smart 'Manufacturing 2025! UVLED inkjet printing technology approaches the home market

The industrial fields that inkjet printing has entered include: 3+axis direct molding (bottle printing), 3D production and value-added products (spray edges, phone cases, etc.), 3D printing

Inkjet printingThe industrial sectors entered include

3+axis direct molding (bottle printing), 3D production and value-added products (spray edges, phone cases, etc.), 3D printing, decorative flooring, decorative glass, decorative building materials, printed electronics, textiles, image display, ceramics, wood, wall decoration, etc

UV inkjet 3D printingWood

As a new type of surface processing technology for sheet metal

Yes, it isultravioletUtilizing digital inkjet under certain conditions

supportUV inkPrinted on the surface of the printing plate

inkInstantly solidified to form a wood grain texture,

The advantage lies inNo need for plate making,

curing processSolvent-free evaporation,

Flexible setting of printing quantity, style, and effect.

During the printing process, UV ink is exposed to UV LED ultraviolet light, and the photoinitiator absorbs light photons, generating free radicals and initiating polymerization reactions of prepolymers. The polymer molecules interact with each other to form a network like solid structure. After the free radicals lose their activity, the chain growth stops and the ink is completely cured. The UV LED curing method can be used for customized flooring and furniture, as well as for large-scale batch production of boards

Traditional decorative panels use adhesive film paper impregnated with amino resin -——

Wood grain on paper printed with traditional steel mold color matching,

Laying on particleboard, fiberboard, etc

The surface of the artificial board substrate is hot pressed

ButDigital printing decorative wood grainboard

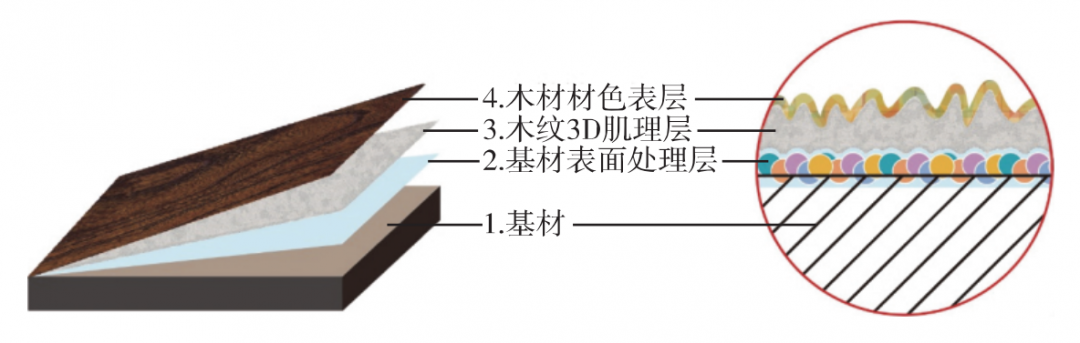

A 3D wood texture board structure model based on UV inkjet printing technology

Reflected in the product structure

No decorative paper layer or adhesive layer

Reduced the number of process steps such as printing paper, dipping glue, and hot pressing

In terms of promoting the development of space, energy, and environment

Surface texture printing on traditional flooring and furniture panels

More green, environmentally friendly, and energy-efficient.

Youweixing Digital Printing UV LED Curing Solution, fromWood grain digital image, printing process scheme, and product interface processingThree aspects provide better solutions

ButUV LED Printing Wood Technologybe based on

The design and production characteristics of digital resources can be integrated with

Store system, design system, production system, logistics management

When the modules are effectively combined

Can be quickly implemented according to customer requirements

Flooring, furniture, wall panels, decorative backgrounds

Waiting for personalized customization of products

Especially withUV LED 3D printing technologyexist

Wallpaper, carpet, floor tiles, curtains, soft pack sofa

The development of other fieldsDigital Printing Technology

Customized home systemThe applications in China are becoming increasingly mature

It will become an important aspect of the development of the custom home industry

-March 2008-

- October 2015 -

Youweixing has started to develop fiber optic, offset printing, label, and LCD curing light source systems, implementing the "Peak Plan" of research and development, and bravely climbing the high-precision and cutting-edge field of UV curing

Strategic cooperation has been established with leading domestic UV ink suppliers to promote offset printing light sources in bulk. As of July 2019, more than 110 units have been installedRanked No.1 in the domestic offset printing machine modification market share;

The successful installation of the company's first high-power LCD curing surface light source marks the successful entry of the company's products into the LCD cell stage process, which is the first of its kind in China

The Youweixing label flexographic curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, opening the door to cooperation with well-known brand label machine manufacturers

The market of UV label, offset printing, LCD and other light source systems of Youweixing has expanded to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, and its overseas performance has achieved rapid growth

Wuhan Youweixing Technology Co., Ltd

Address: 5th Floor, Building B, R&D Building 1, Modern Service Industry Base, Huagong Science and Technology Park, Donghu New Technology Development Zone, Wuhan City

Postal Code: 430223

Contact number: (+86) 027-87971689

Contact email: sales@uvledtek.com (Sales)