As a technological pioneer in cigarette packaging printing, how to alleviate industry anxiety about the future

Green+Smart=Printing Future

Cigarette product packaging is different from other product packaging and has its own characteristics. It is currently the most exquisite and technologically advanced packaging product, integratingPackaging design, high-tech materials, printing technology, information technologyVarious technologies are needed

Based on the uniqueness of cigarette packagingMany new printing process technologies were first applied to cigarette packaging after research and developmentTherefore, the development level of cigarette packaging can represent the application level of printing technology in China

With the continuous integration of advanced sensing technology, automatic control technology, and color management technology to meet the goal of cross media integration in printing. The packaging printing technology in our country has already taken shapeOffset printing, flexographic printing, gravure printing, screen printing, and digital printingCoexistence of industrial patterns

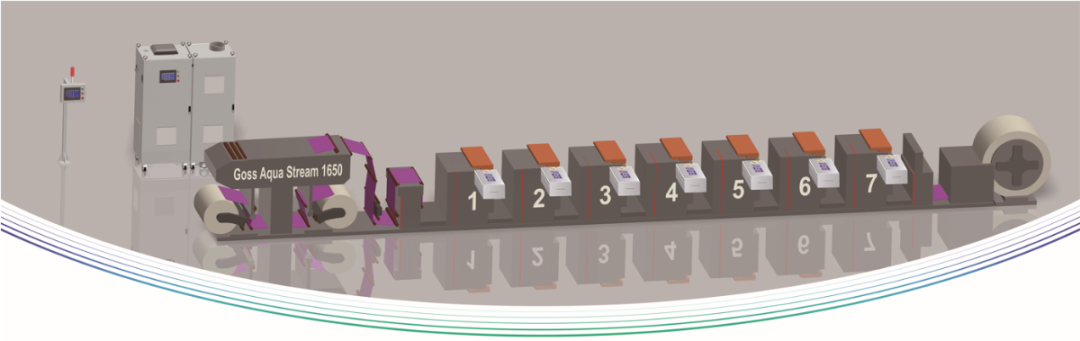

offset printing

Offset printing is a printing method that utilizes the principle of oil and water being immiscible, and uses a rubber blanket to transfer the graphic and textual information on the offset printing plate to the substrate. The graphic and textual information of offset printing plates is hydrophilic, while the non graphic and textual parts are hydrophilic. The printing plate is almost flat, so it is also called offset printingOffset printing is widely used in cigarette packaging products, with high printing quality, rich colors, and good image layeringThe characteristics of offset printing are highly sought after by major cigarette brandsHigh printing efficiencyIt can also meet the rapidly growing demand for cigarette product sales

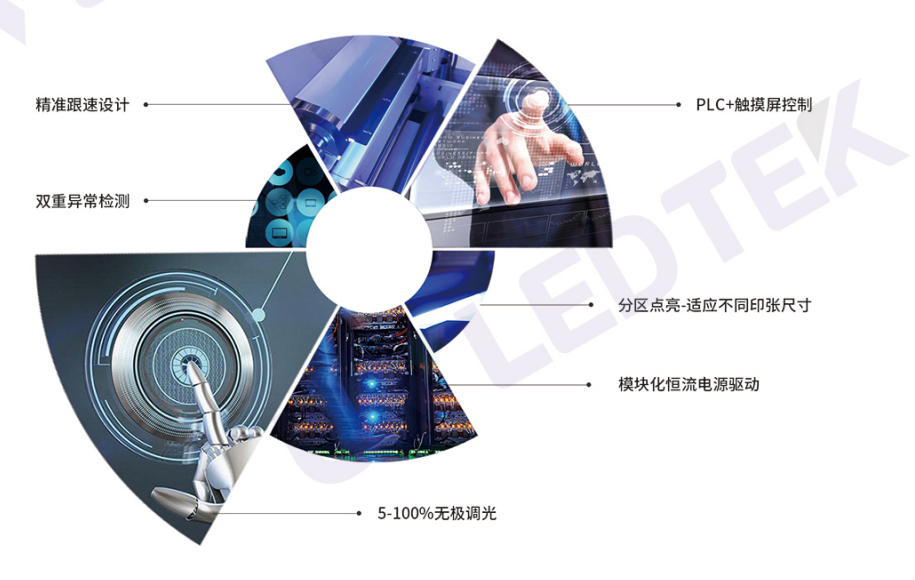

The Youweixing offset printing light source system has corresponding curing solutions for all five major models

Youweixing white ink light source, specially designed for packaging printingResearch and developmentNo matter what the quality of the paper is, there will be no ink pulling or stacking

Flexographic printing

Flexographic printing is a printing method that uses a flexible photosensitive resin plate to transfer ink through a mesh roller. Due to the protruding graphic and textual information of the plate, it also belongs to a type of relief printing. Flexographic printing plates are photosensitive resin plates with a thickness of 1mm to 5mm. Flexographic printing has a thicker ink layer, which is between offset printing and gravure printingColor stability, high printing efficiency, green and environmentally friendly ink, have been widely used in food packagingFlexographic printing is less commonly used in cigarette packaging, and is mainly used in the tobacco industryThe cardboard boxes for cigarettes are printed using flexographic printingMethod

The Youweixing flexographic printing light source system has corresponding curing solutions for various models

The Youweixing flexographic printing light source can meet the current maximum printing speed requirements

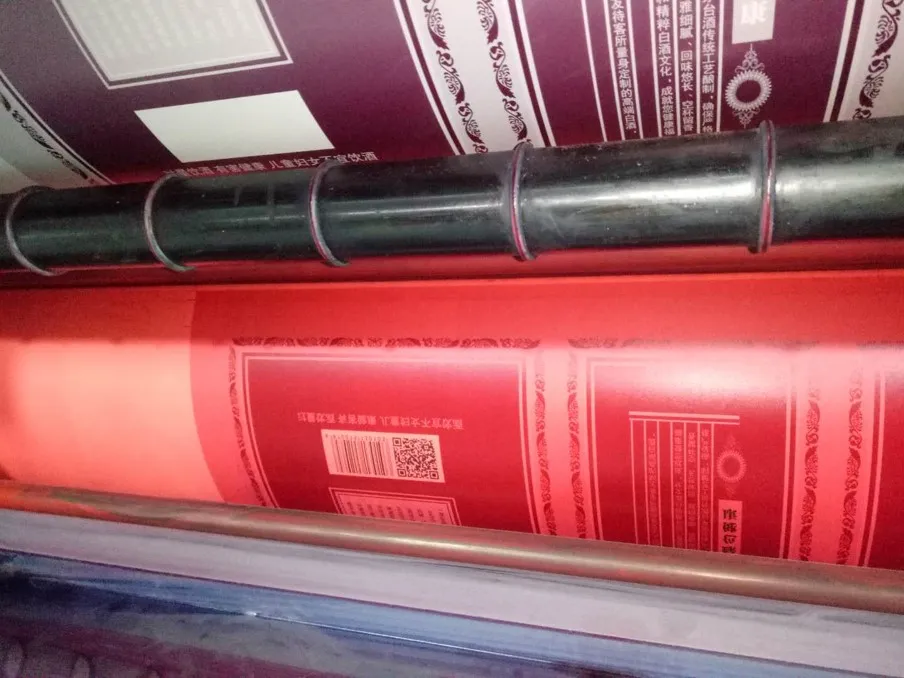

intaglio printing

Concave printing is a concave graphic printing plateDirectly imprint ink onto the substrateThe printing method. The depth of the concave pits on the printing plate determines the intensity and layering of the ink. If the pits are deep, the printed ink layer will be thicker; On the contrary, if the pit is shallow, the printed ink layer will be thinnerThe ink layer of gravure printed packaging products is thick, with a good sense of layering, bright ink colors, high saturation, stable product quality, high printing efficiency, and very durable printing plates. It is generally used for cigarette products with particularly high demand

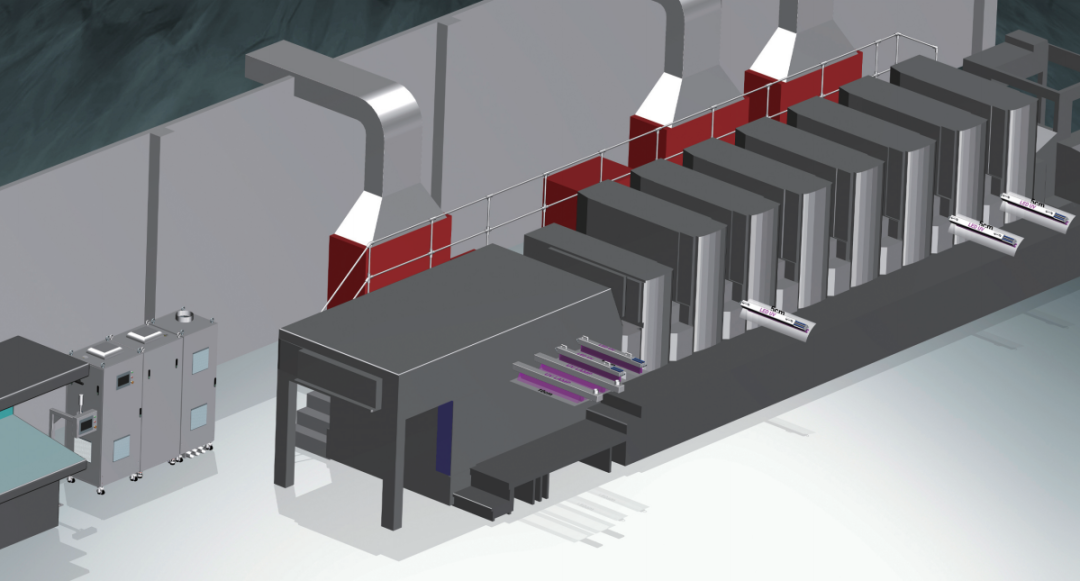

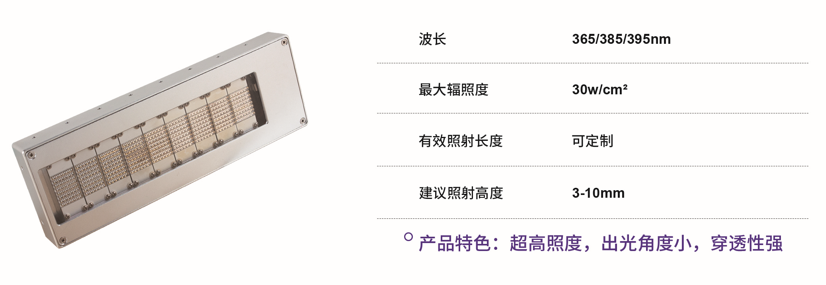

Youweixing LED UV light source, ultra-high illumination, strong penetration

screen print

Screen printing is a printing method that utilizes the principle that the mesh holes in the graphic and textual parts of a screen printing plate can pass through ink, and is manually or semi automatically scraped to transfer ink onto the substrate through the mesh holesScreen printing ink layer is the thickest among the four printing methods(Ink layer can reach 30-100 μ m), silk screen ink layerIt has a strong tactile and three-dimensional feel, and can create effects such as ice flowers and wrinkles. It is widely used to express the special texture of cigarette packaging surfaces and enhance the grade of cigarette products

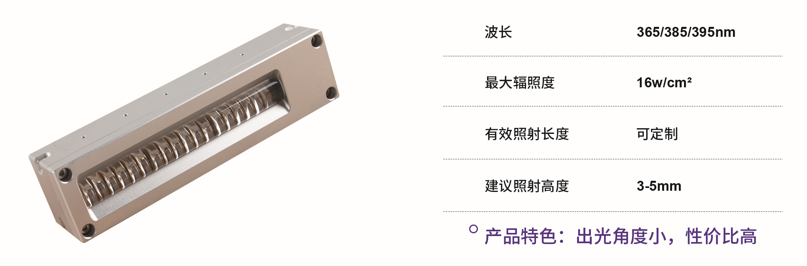

Uniform light output and high cost-effectiveness

digital printing

Digital printing is a printing method that converts computer graphic and textual information into data and directly prints it on paper using printing equipment. It completely breaks through the basic process of traditional printingAchieved one-time completion of no printing plate, dynamic data, and full-color images, It is a new type of printing method

Ultra thin, small light emission angle, strong directionality

The biggest feature of digital printing is its lack of printing and variable information, which integrates various technologies such as printing, electronics, computers, networks, and communication. Currently, digital printing technology has low production efficiency and insufficient stabilityMainly used for research and development sampling of cigarette packaging and small-scale printing of cigarette packaging trademarks

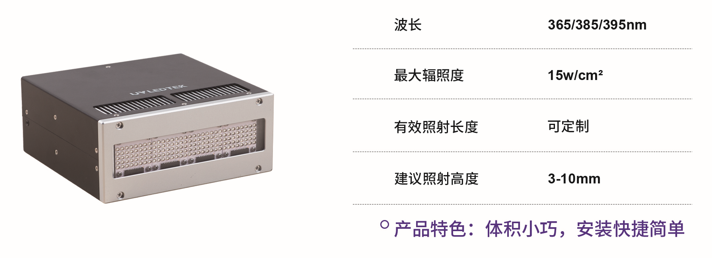

Compact size and convenient application

onlyThe emergence of digital printing technology has greatly improved the research and development efficiency of cigarette packagingCompleting a cigarette packaging sample using traditional printing methods takes one to two days, while digital printing only takes about an hour

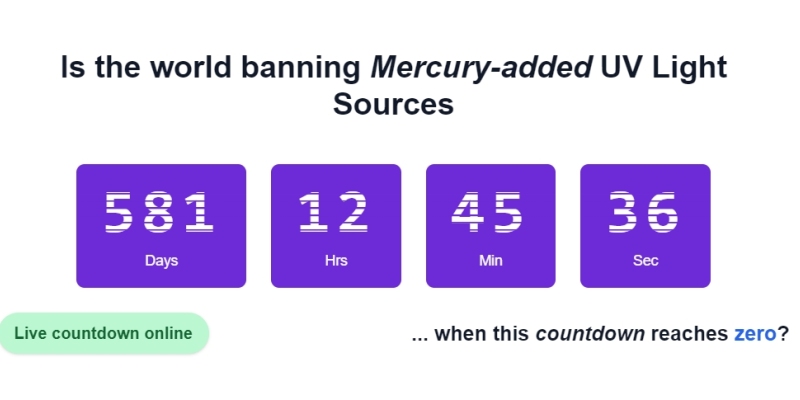

The State Administration of Press, Publication, Radio, Film and Television clearly stated in the "13th Five Year Plan for the Development of the Printing Industry" that by the end of the 13th Five Year Plan periodThe proportion of green printing output value to the total printing output value exceeds 25%, while digital printingAnnual compound growth rate exceeding 30%

Green printing does not refer to a specific printing technology, but rather a concept that ensures the environmental protection of printed products throughout their entire lifecycle, including raw materials, production, sales, use, recycling, and reuseGreen environmental protection is the mainstream trend of global development and a manifestation of social responsibility. Green printing is also the future development trend of the printing industryAround this concept, more intelligent printing technology has been developed and applied to cigarette packaging

In this trend of intelligent upgrading, traditional cigarette packaging has realized the importance of closely integrating cutting-edge technology, As a driving force for technological innovation in the printing industry, the future of cigarette packaging is inevitably green and intelligent

-March 2008-

- October 2015 -

Youweixing has started to develop fiber optic, offset printing, label, and LCD curing light source systems, implementing the "Peak Plan" of research and development, and bravely climbing the high-precision and cutting-edge field of UV curing

Strategic cooperation has been established with leading domestic UV ink suppliers to promote offset printing light sources in bulk. As of July 2019, more than 110 units have been installedRanked No.1 in the domestic offset printing machine modification market share;

The successful installation of the company's first high-power LCD curing surface light source marks the successful entry of the company's products into the LCD cell stage process, which is the first of its kind in China

The Youweixing label flexographic curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, opening the door to cooperation with well-known brand label machine manufacturers

The market of UV label, offset printing, LCD and other light source systems of Youweixing has expanded to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, and its overseas performance has achieved rapid growth

Wuhan Youweixing Technology Co., Ltd

Address: 5th Floor, Building B, R&D Building 1, Modern Service Industry Base, Huagong Science and Technology Park, Donghu New Technology Development Zone, Wuhan City

Postal Code: 430223

Contact number: (+86) 027-87971689

Contact email: sales@uvledtek.com (Sales)