What role does LED UV play in the field of optical communication that countrymen are proud of

Regarding fiber optic coloring

Our country's technology is undergoing rapid changes, and in the field of optical communication, LED UV, with its unique advantages, can participate inPlaying an important role in it

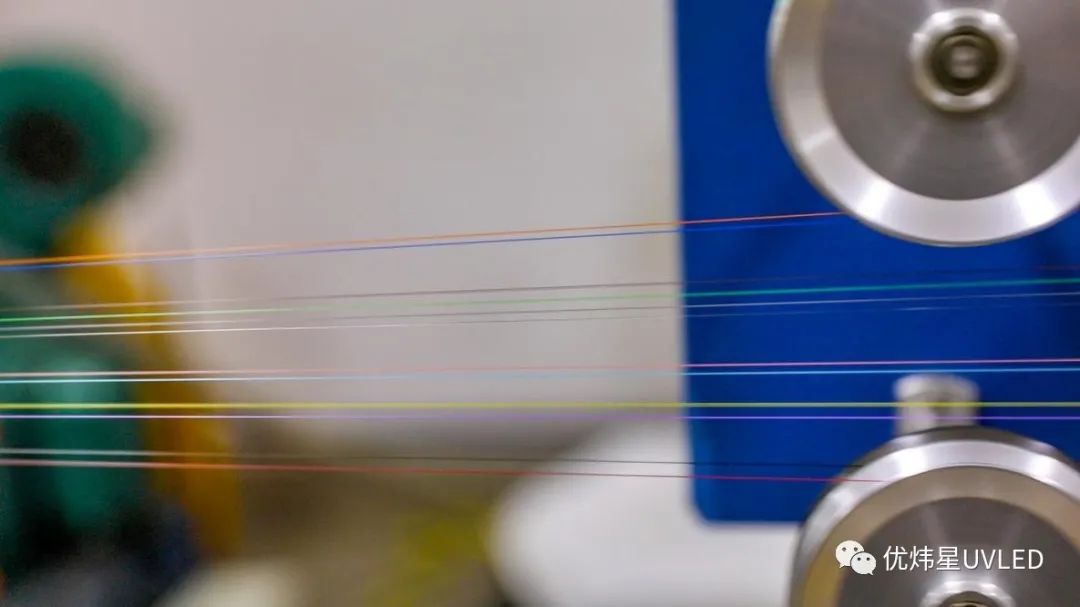

Fiber optic coloring

After passing through the coloring mold, the natural fiber is dyed with ink, and thenUV curing ovenCure the ink under ultraviolet light to form a surface gloss with uniform thicknessFiber optics with different colorsThis is where traditional UV mercury lamps and modern LED UV lamps play a role in this process

There have been many drawbacks in the early application of UV mercury lamps

60% of the energy in mercury lamps is emitted through light radiation or high temperature, resulting in significant energy waste and requiring additional layout of blowers, etc

At startup, electrode discharge will cause the breakdown of air and generate ozone, damaging the production environment

Mercury itself is a highly toxic substance, and ink emits certain organic gases (VOCs) at high temperatures, causing air pollution and not meeting environmental protection requirements

LED UV is replacing traditional UV mercury lamps as the mainstream application

LED-UV lamps have a concentrated wavelength and can be customized according to the wavelength of the UV ink used. They have high energy concentration, minimal light radiation waste, and do not require the installation of a heat dissipation blower

It can achieve a lifespan 15 times longer than ordinary mercury lamps, can be turned on and used at any time, has a small size, and is very flexible in application and placement on the production site

No VOCs gas emissions, no ozone generation, safe, energy-saving and environmentally friendly

If the temperature inside the curing furnace exceeds 120 ℃, it will affect the attenuation of the optical fiber, and if it exceeds 150 ℃, it may cause damage to the optical fiber. The temperature inside the LEDUV curing oven can be controlled within 80 ℃, which is beneficial for the benign rate of optical fiber products

The trend of future intelligent manufacturing is to achieve integrated production through equipment improvement and production process optimizationAs a cutting-edge technology, the application of modern technology in optical communication is essential

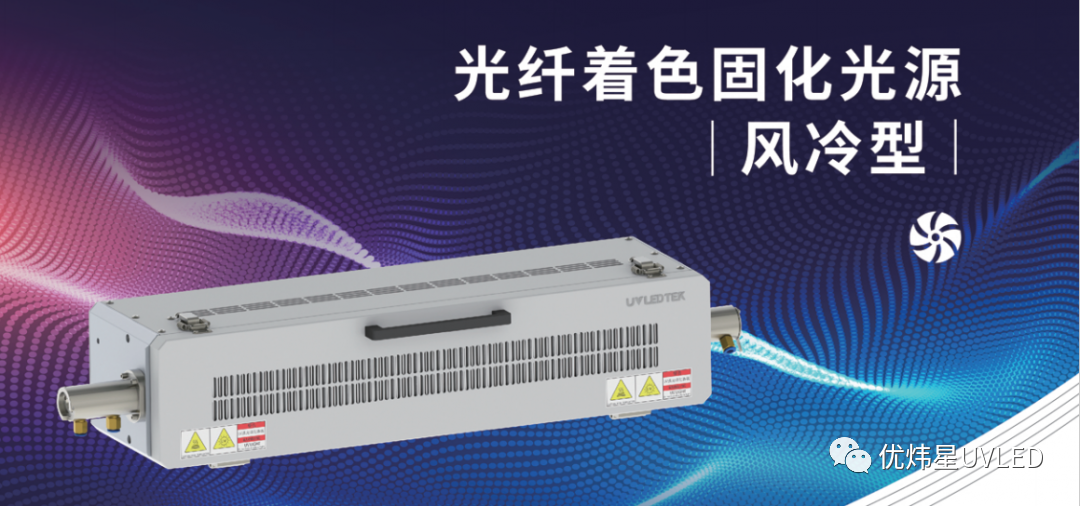

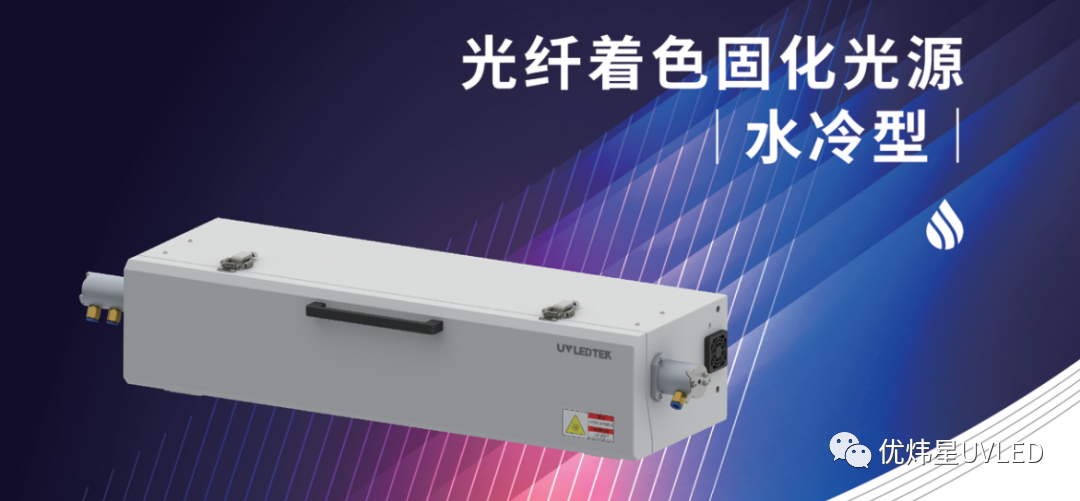

We have developed two types of fiber optic coloring light sources, air-cooled and water-cooled, to meet the different application environments and production conditions of users. Performed well in practical applications with partners

besidesThe matching between the speed of the production line and the power of the curing furnace is very important in the coloring process. Especially during the acceleration and deceleration process, if the power is too low or the speed is too fast, it will lead to insufficient curing and color fading. Excessive power and slow speed can lead to over curing, detachment of the fiber curing layer, and fiber bending

The LED UV light source provided by Youweixing for the fiber optic industry is equipped with an intelligent control systemThe output power and other parameters can be flexibly adjusted according to on-site needs, and the best matching mode can be debugged with professional manual services. Maximize production efficiency

-March 2008-

- October 2015 -

Youweixing has started to develop fiber optic, offset printing, label, and LCD curing light source systems, implementing the "Peak Plan" of research and development, and bravely climbing the high-precision and cutting-edge field of UV curing

Strategic cooperation has been established with leading domestic UV ink suppliers to promote offset printing light sources in bulk. As of July 2019, more than 110 units have been installedRanked No.1 in the domestic offset printing machine modification market share;

The successful installation of the company's first high-power LCD curing surface light source marks the successful entry of the company's products into the LCD cell stage process, which is the first of its kind in China

The Youweixing label flexographic curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, opening the door to cooperation with well-known brand label machine manufacturers

The market of UV label, offset printing, LCD and other light source systems of Youweixing has expanded to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, and its overseas performance has achieved rapid growth

Wuhan Youweixing Technology Co., Ltd

Address: 5th Floor, Building B, R&D Building 1, Modern Service Industry Base, Huagong Science and Technology Park, Donghu New Technology Development Zone, Wuhan City

Postal Code: 430223

Contact number: (+86) 027-87971689

Contact email: sales@uvledtek.com (Sales)