mighty wave crashing on a sandy shore! Green printing is roaring towards us

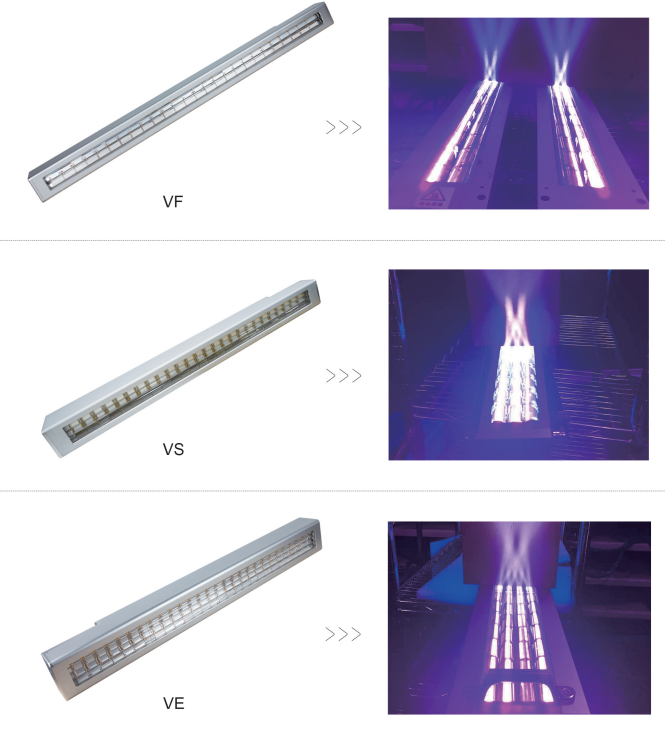

LED UV light source, helping green and environmentally friendly printing

With the rapid development of global industry, environmental protection has become one of the most important issues in the world. Consumers are increasingly concerned about the issue of toxic and harmful substances in consumer goods. The harmful substances such as formaldehyde and volatile organic compounds contained in printed materials pose a significant threat to human health. Implementing the national strategy for sustainable quality development and green printing is of great significance for implementing relevant central policies, promoting industrial development, and advancing energy conservation and emission reduction to promote sustainable development

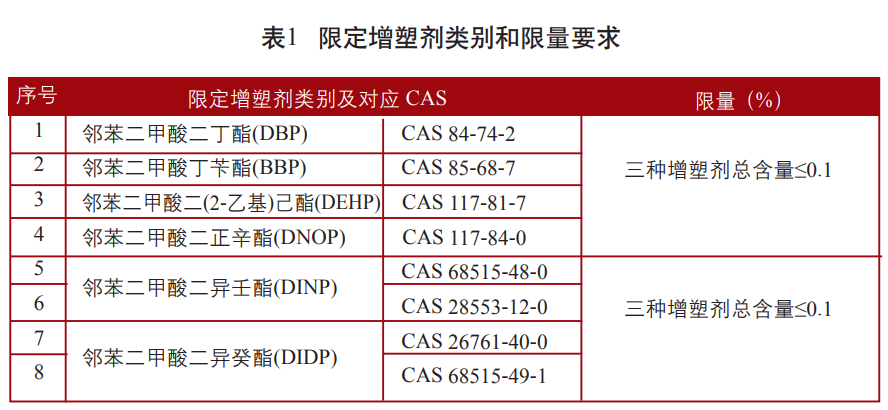

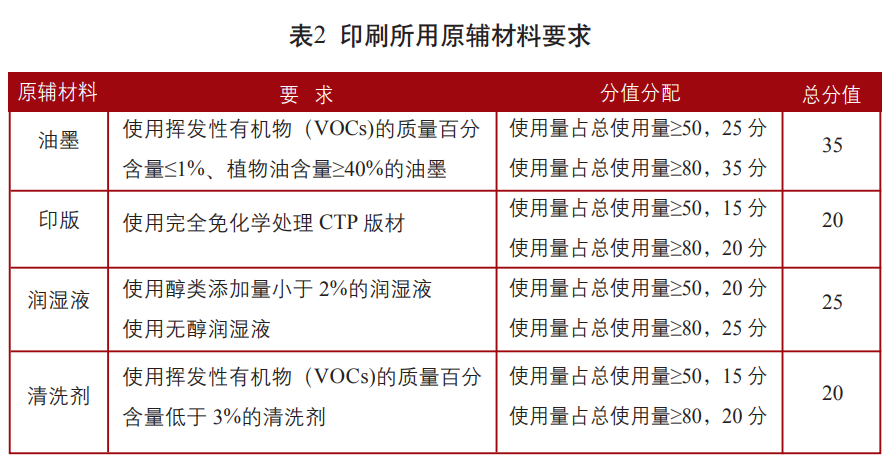

Green printing refers toUsing environmentally friendly materials and processes, the printing process generates less pollution, saves resources and energy, and makes printed materials easy to recycle and reuse after being discardedA printing method that is recyclable, naturally degradable, and has minimal impact on the ecological environment

The flash point of the cleaning agent should be higher than 60 ℃, and kerosene or gasoline should not be used as cleaning agents. The flash point determination shall be carried out in accordance with the provisions of GB/T 21775-2008

At present, our country hasOver 100000 householdsA printing enterprise with 3.56 million employees and an annual output value of 867.7 billion yuanWorld Printing Power.

However, regardless of their size, printing enterprises in our country are all moving forward in a homogeneous development modelThe implementation of green printing by the country will rapidly strengthen some excellent enterprisesSimultaneously guide enterprises with certain conditionsBy upgrading technology to meet qualified standards, enter the international stage

A series of national policies have guided the printing industry to firmly follow the path of green development during the 14th Five Year Plan period, and the concept of "carbon peak and carbon neutrality" has deeply penetrated people's hearts. As one of the four key industries for VOCs control in the country Printing enterprises should embrace trends, actively respond to the concept of green development, continuously improve the level of green and low-carbon technology and processes, empower pollution reduction and emission reduction through multiple paths, and achieve green upgradingEmbark on the path of sustainable development

-March 2008-

- October 2015 -

Youweixing has started to develop fiber optic, offset printing, label, and LCD curing light source systems, implementing the "Peak Plan" of research and development, and bravely climbing the high-precision and cutting-edge field of UV curing

Strategic cooperation has been established with leading domestic UV ink suppliers to promote offset printing light sources in bulk. As of July 2019, more than 110 units have been installedRanked No.1 in the domestic offset printing machine modification market share;

The successful installation of the company's first high-power LCD curing surface light source marks the successful entry of the company's products into the LCD cell stage process, which is the first of its kind in China

The Youweixing label flexographic curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, opening the door to cooperation with well-known brand label machine manufacturers

The market of UV label, offset printing, LCD and other light source systems of Youweixing has expanded to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, and its overseas performance has achieved rapid growth

Wuhan Youweixing Technology Co., Ltd

Address: 5th Floor, Building B, R&D Building 1, Modern Service Industry Base, Huagong Science and Technology Park, Donghu New Technology Development Zone, Wuhan City

Postal Code: 430223

Contact number: (+86) 027-87971689

Contact email: sales@uvledtek.com (Sales)