Specialized for packaging printing LED UV light source

White ink is widely used in packaging and other printing processes. In order to present exquisite patterns, Improve barcode readability, Cover the background color of the original printing material to accurately restore it

White ink is widely used in packaging and other printing processes.

In order to present exquisite patterns, Improve barcode readability, Covering the background color of the original printing material to accurately restore the image, Bai Mo Duo as the first 1 Color and rank 2 Color is used for printing, On this basis, print other colors.

but, The result of this is the strength of the adhesion of white ink on printed materials, It will directly affect the qualification rate of printed materials.

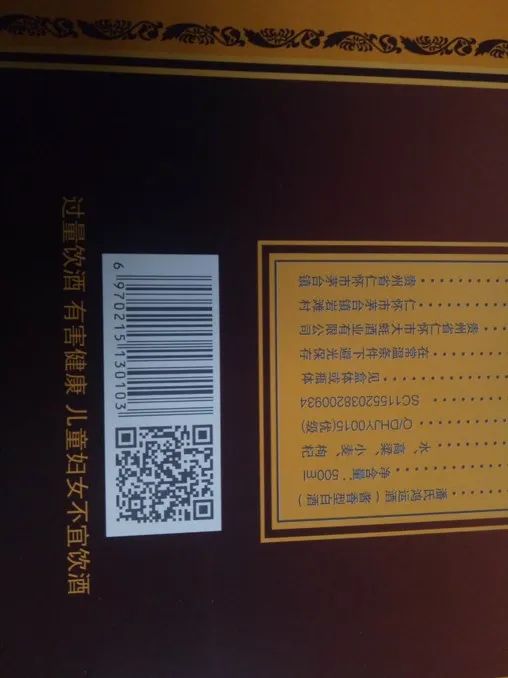

for example: A certain printing factory is producing a certain type of cigarette box, The barcode level is not qualified, Causing downtime and waste. After further observation under a microscope, it was found that, There are large and numerous light spots in the unqualified barcode area. in other words, The white ink in the unqualified barcode area has low adhesion on the laser card, The white ink base is not solid enough, Causing the inability to completely cover the gloss of the laser cardboard, Ultimately leading to the barcode being non compliant.

Therefore, Improving the adhesion of white ink on printed materials is of crucial and important significance for practical production.

with LED Gradually replacing mercury lamps, Generally used in the market 385 band LED Use a light source to solidify white ink, But the effect is often not good, Easy to cause ink pulling in printed materials, The phenomenon of rubber ink accumulation, The quality of the finished product is very unstable.

The Youweixing R&D team is addressing this situation, Specially developed a new model for white ink curing LED lamp - White ink curing lamp, Solved the problem of white ink solidification faced by printing enterprises at the current stage.

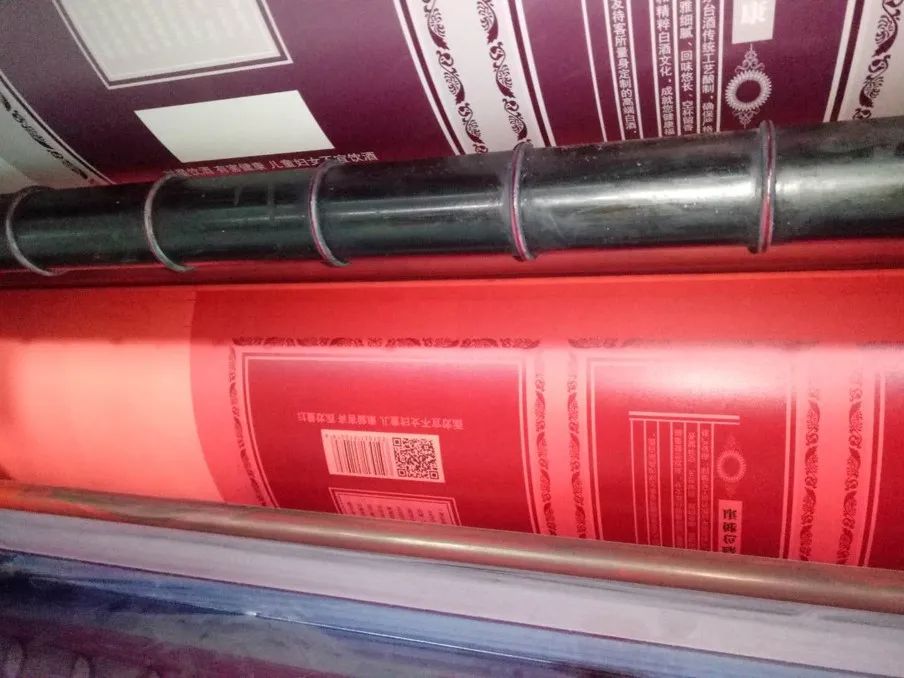

At the packaging printing machine customer's location that cooperates with our company, We use mainstream ink brands Hanghua and ordinary ink respectively UV ink, Conducted multiple attempts at printing, result (Slide up and down to view) :

Compared to the general ones on the market 385 band LED Compared to lamps, Excellent performance of Youweixing white ink lamp, There is no phenomenon of ink pulling at all, surface drying, Rubber without pile white ink.

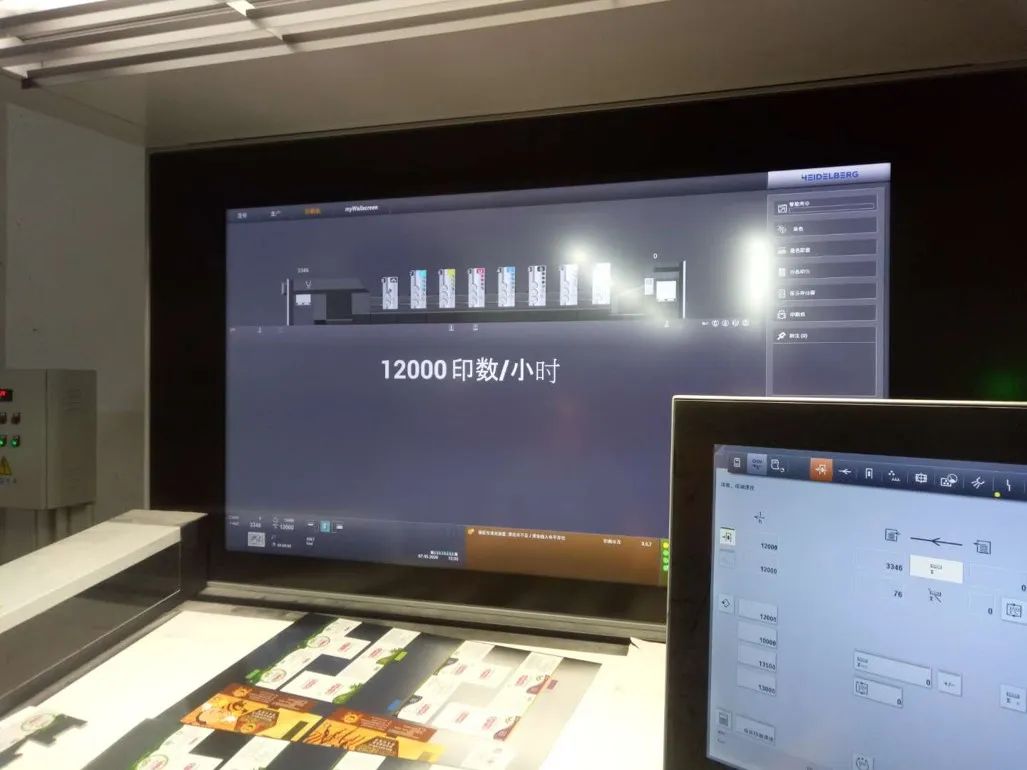

When the test printing speed reaches 12000 printing/hour, ordinary LED Silver polyester under lamp illumination, Jin Su Mian, Silver laser and other printing materials, paper, There may be slight or severe ink pulling depending on the quality of the paper.

The quality of the printed materials under the illumination of the Youwei Star white ink lamp is very stable, Regardless of the quality of the paper, There was no occurrence of ink pulling, The phenomenon of ink accumulation.

Jin Su Mian Material, No ink , good effect

Rubber without ink accumulation, Clean surface

- 2008 year 03 moon -

- 2015 year 10 moon -

UVLEDTEKg begins to develop optical fibers, Offset printing, label, Liquid Crystal Curing Light Source System, Implementing research and development "Peak Climbing Plan" , Brave Climbing UV High precision and cutting-edge fields of solidification;

Compared to domestic UV Leading ink supplier reaches strategic partnership, Batch promotion of offset printing light sources, as of 2019 year 7 Installed monthly 110 Above the stage, Market share of domestic offset printing machine modification NO. 1;

The company's first high-power LCD curing surface light source was successfully installed in one go, Mark the successful entry of the company's products LCD cell Duan Craft, For the first time in China;

UVLEDTEKg label flexographic printing curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, Open the door to cooperation with well-known brand label machine manufacturers;

Youwei Star UV label, Offset printing, Expansion of LCD and other light source system markets to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, Rapid growth in overseas performance.

Wuhan UVLEDTEKg Technology Co., Ltd

address: Wuhan Donghu New Technology Development Zone Huagong Science and Technology Park Modern Service Industry Base 1 R&D Building B seat 5 building

postal code: 430223

Contact Number: (+86) 027-87971689

Contact email: sales@uvledtek. com (sales)