Good helper for white ink printing| LED UV White Ink Lamp

first time right, No more waste.

LED UV The basic principle of offset printing curing is that the photoinitiator in the ink absorbs ultraviolet radiation energy and is activated, The outer electrons of its molecule undergo hopping, Generate active centers in a very short period of time, Then the active center interacts with the unsaturated groups in the resin, Double bond cleavage in luminescent cured resin and reactive diluent molecules, Continuous polymerization reaction occurs, Thus, they crosslink with each other to form a film, A type of radiation curing method.

In recent years, LED UV Gradually replacing tradition UV mercury lamp

The truly usable energy of traditional mercury lamps in productionQuantity only20~25%, The rest are visible light and heat, Great energy waste, And it will release ozone, Not friendly to the production environment of printing factories;

UV The effective service life of mercury lamps is only 800-1000 hour, For a continuously operating printing factory, 1 It will be replaced in over a month 1 Secondary light tube, Long term use costs are extremely high;

UV Once the mercury lamp is used beyond its lifespan, The power will significantly decrease, As a result, inferior printed products appeared, Cause losses. However, the current mercury lamp systems on the market are often not intelligent enough, Unable to automatically monitor usage time;

LED UV Printing does not release solvents into the environment

Can meet the strictest requirements VOC Emission regulations

in use UV During the process of ink printing, due toTransparency of ink of different colorsThere are significant differences, So their absorption levels of ultraviolet rays vary, Will affect the overall drying speed.

so, Usually, we follow thewhite, black, green, Huang, Pinhong InkArrange the color sequence, Make ink with poor transparency absorb as much as possible UV illumination, So that the final printing speed and color can reach the optimal level.

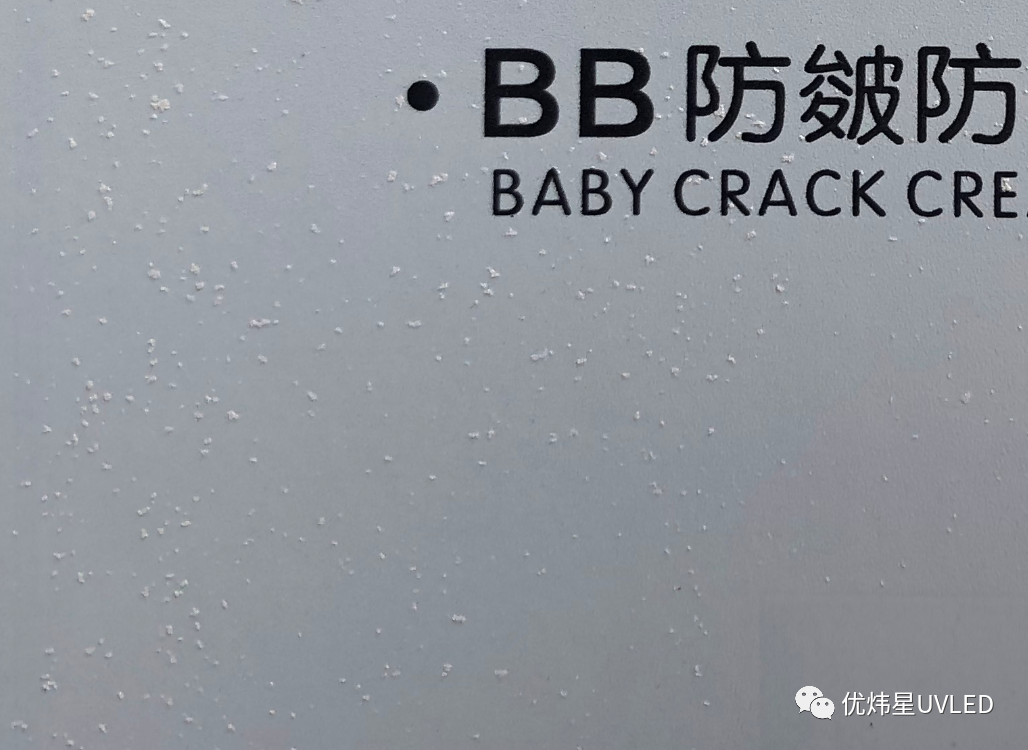

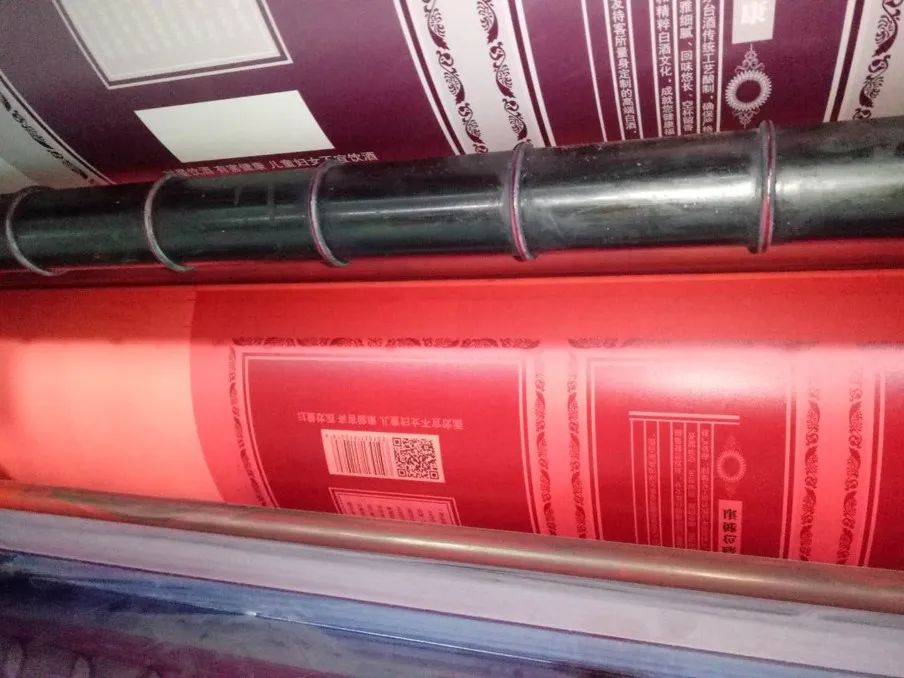

(Use regular LED UV The white ink exposed to the light source has severe ink pulling)

White ink belongs to the total reflection spectrum, due to UV Light is not easily transmitted, Sometimes harder to cure than black ink.

(Obvious graininess)

Many printing factories, especially those engaged inpackage printingtime, We will encounter the problem of difficult solidification of white ink. at LED UV In the application, This is also a major challenge within the industry.

But the printing speed determines the production efficiency of the printing factory, howQuickly complete white ink curing, Ensuring print quality while improving production efficiencythen?

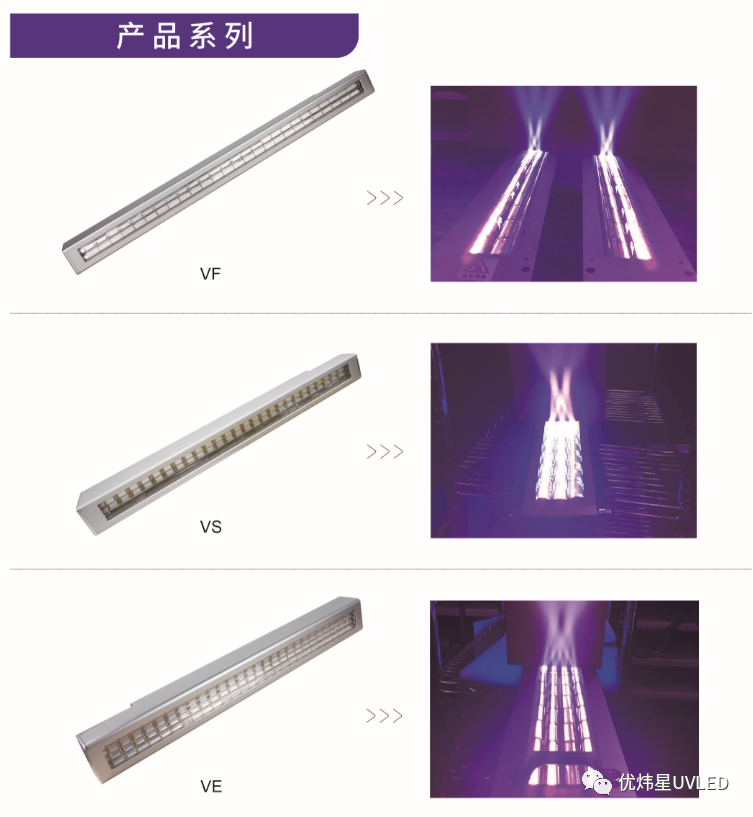

Based on the characteristics of white ink and the actual production scenarios of printing, Youwei Star has specially developedWhite ink curing lamp, Excellent performance in on-site experiments and subsequent use at the cooperative printing factory.

Printed matterThere is no such thing as ink pullingThe phenomenon, surface drying, Rubber without pile white ink.

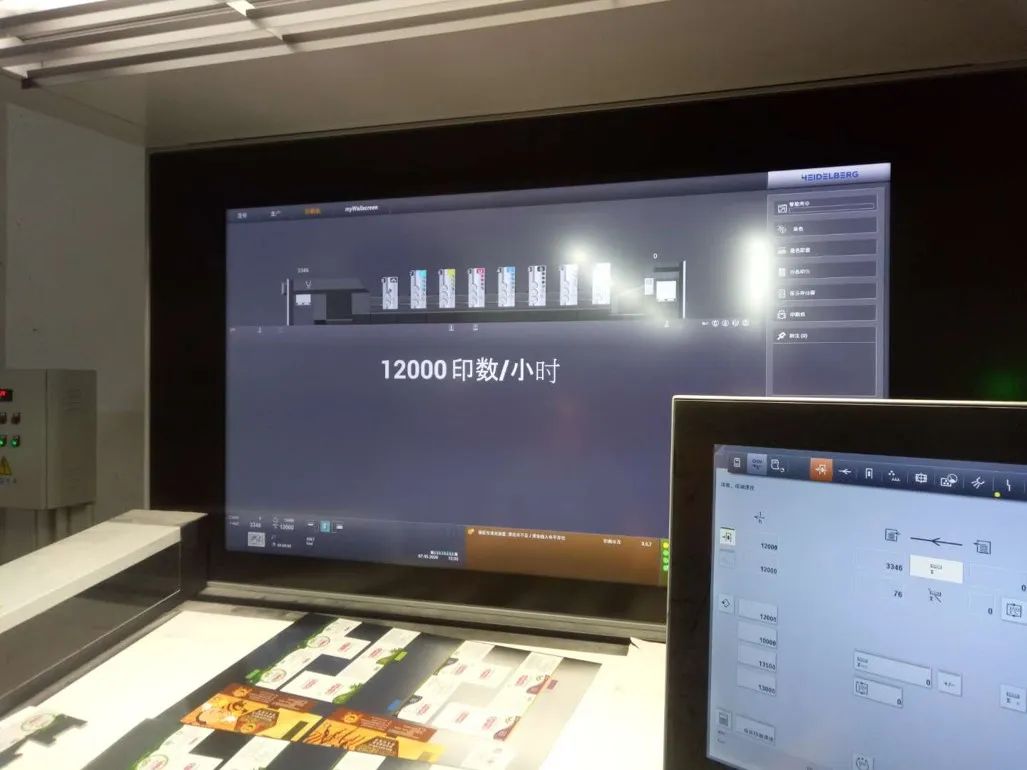

When the test printing speed reaches 12000 printing/hour, ordinary LED Under the illumination of the lampSilver polyester, Jin Su Mian, Silver laser and other printing materials, paper, It will be based on the quality of the paperThere may be slight or severe ink pullingphenomenon.

ButYouwei StarWhite Ink LampThe quality of the printed material under illuminationVery stablefixed, Regardless of the quality of the paper, allThere was no occurrence of ink pulling, Stacking inkThe phenomenon.

Jin Su Mianmaterial, No ink , good effect

rubberNo ink accumulation, Clean surface

- 2008 year 03 moon -

- 2015 year 10 moon -

UVLEDTEKg begins to develop optical fibers, Offset printing, label, Liquid Crystal Curing Light Source System, Implementing research and development "Peak Climbing Plan" , Brave Climbing UV High precision and cutting-edge fields of solidification;

Compared to domestic UV Leading ink supplier reaches strategic partnership, Batch promotion of offset printing light sources, as of 2019 year 7 Installed monthly 110 Above the stage, Market share of domestic offset printing machine modification NO. 1;

The company's first high-power LCD curing surface light source was successfully installed in one go, Mark the successful entry of the company's products LCD cell Duan Craft, For the first time in China;

UVLEDTEKg label flexographic printing curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, Open the door to cooperation with well-known brand label machine manufacturers;

Youwei Star UV label, Offset printing, Expansion of LCD and other light source system markets to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, Rapid growth in overseas performance.

Wuhan UVLEDTEKg Technology Co., Ltd

address: Wuhan Donghu New Technology Development Zone Huagong Science and Technology Park Modern Service Industry Base 1 R&D Building B seat 5 building

postal code: 430223

Contact Number: (+86) 027-87971689

Contact email: sales@uvledtek. com (sales)