In the forming process of ribbon fiber optic cable and optical fiber ribbon, LED UV What kind of function does it have?

An important link that cannot be ignored in fiber optic cable bundling.

With the entry of fiber optic cables into households (FTTH) The rapid development of, 20 century 90 At the beginning of the year "Eight vertical and eight horizontal" The core density and cable diameter of the traditional loose layer twisted fiber optic cable used in the fiber optic trunk network can no longer fully meet the needs of users.

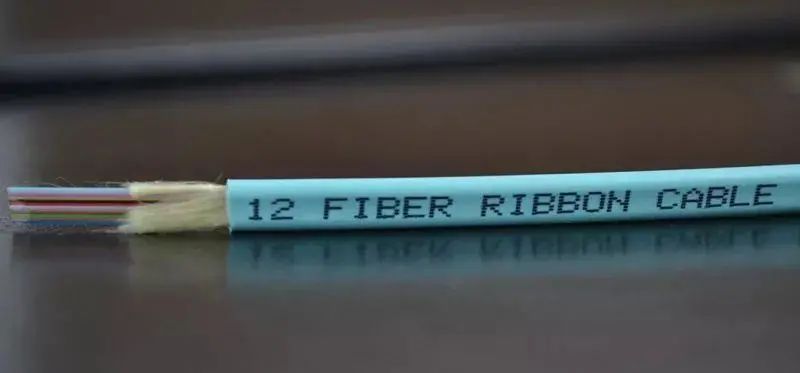

high fiber count, high density, Large capacity ribbon cables rely on their high speed, high fidelity, The characteristics of access networks are gradually replacing traditional optical cables, Becoming the main transmission medium in application scenarios.

During this transformation process, Fiber optic ribbon with its high density, small size, Convenient connection, Characteristics of easy branching, Becoming the preferred form of high core fiber optic cable.

To ensure high-quality core interconnection and save time and effort during the construction and splicing of ribbon cables, All manufacturers are exploring ways to improve their processes.

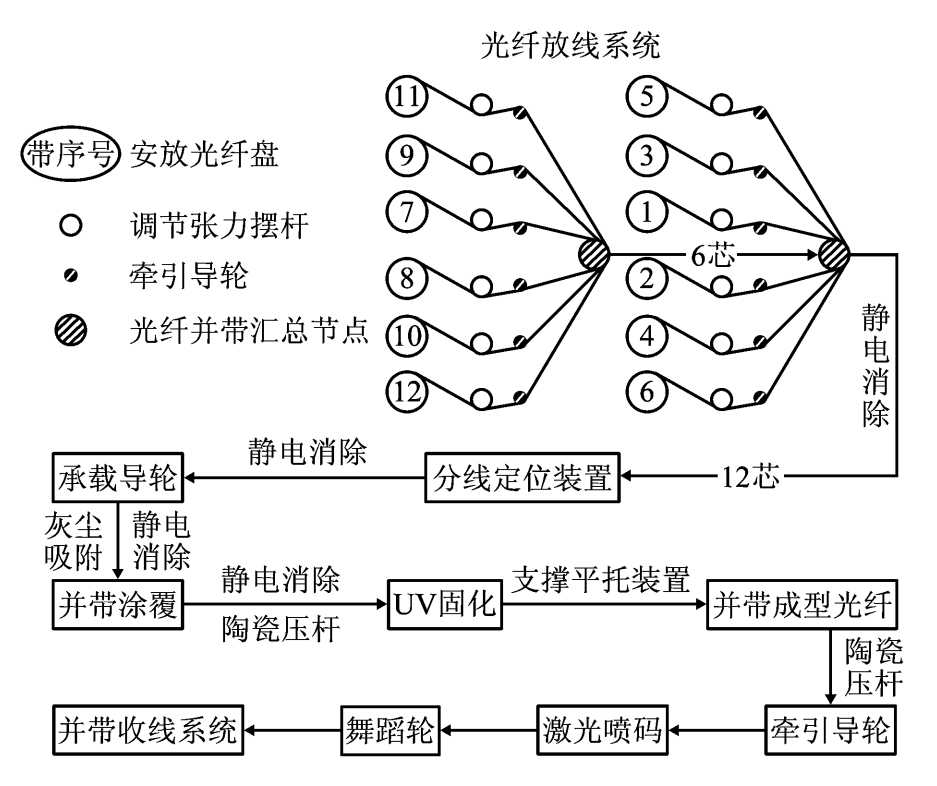

During the process of forming ribbon shaped optical fibers, To ensure a smooth surface of the optical fiber, Consistent length, No bending deformation, etc, People often pay close attention to itControl of cleanliness of colored optical fibers, Control of Static Electricity in Colored Optical Fiber, Control of tension in unwinding, And the control of coating mold size and placement position, Control of coating processwait.

actually, UVThe control of the curing process is also crucial for improving overall quality.

The front and back of the fiber optic ribbon coated with acrylic resin need to be evenly distributed UV irradiate, To avoid the occurrence of fiber optic ribbon after forming and bundling "Semi-circular shape" or "half8glyph" phenomenon, Usually, careful adjustments are required before production, Ensure that the fiber optic ribbon is in place UV Uniform and consistent lighting.

Youwei Starlight Fiber and Belt Products: Newly designed, Compare the optical scheme for light emission, Can allow both sides to solidify uniformly at the same time, Ensure and bring straight, Will not deform or bend. Installation and operation are simpler, fast.

In high-speed production (≥500m/min) under the circumstances, Ensuring the cleanliness of quartz tubes has always been a challenge in the technology of uniform solidification. High intensity production easily causes the resin coated on the surface of the optical fiber to splash and adhere to the quartz tube wall, Thereby reducingUVTransmittance of light, Affects curing degree.

Youwei Starlight Fiber and Belt Products: Using high-performance axial fans, Can effectively reduce the deposition of attachments on the inner wall of the central tube. simultaneously, Adopting modular design, maintenance, Replacement is very convenient.

When dust adheres to the surface of the reflector or there are burrs and spots present, Will cause reflectionUVUneven distribution of light, This can lead to curing cracks or uneven thickness of the coated acrylic resin, And with poor flatness. Regular inspection of the reflector is required, clean, And handle with care when disassembling and assembling the outer cover of the curing oven, To avoid scratches.

Youwei Starlight Fiber and Belt Products: Adopting modular design, Having lightweight, compact size, The characteristics of easy installation and maintenance, Can help reduce product defect rates caused by daily cleaning.

The exhaust gas generated during the curing of resin lingers in the quartz tube for a long time, Easy to produce sedimentation, Make the quartz tube yellow or black; At the same time, in order to ensure the compatibility between the ink on the surface of the colored optical fiber and the acrylic coating resin, as well as the absence of bubbles or impurities embedded between the two, We usually fill the quartz tube with nitrogen gas, To discharge the small amount of oxygen and waste gas generated during resin curing inside the quartz tube.

Youwei Starlight Fiber and Belt Products: Adopting a completely new thermal design, While taking away the heat from the chip, it can effectively discharge the tail smoke generated by the curing of the coating, Does not affect the temperature of the central pipe.

- 2008 year 03 moon -

- 2015 year 10 moon -

UVLEDTEKg begins to develop optical fibers, Offset printing, label, Liquid Crystal Curing Light Source System, Implementing research and development "Peak Climbing Plan" , Brave Climbing UV High precision and cutting-edge fields of solidification;

Compared to domestic UV Leading ink supplier reaches strategic partnership, Batch promotion of offset printing light sources, as of 2019 year 7 Installed monthly 110 Above the stage, Market share of domestic offset printing machine modification NO. 1;

The company's first high-power LCD curing surface light source was successfully installed in one go, Mark the successful entry of the company's products LCD cell Duan Craft, For the first time in China;

UVLEDTEKg label flexographic printing curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, Open the door to cooperation with well-known brand label machine manufacturers;

Youwei Star UV label, Offset printing, Expansion of LCD and other light source system markets to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, Rapid growth in overseas performance.

Wuhan UVLEDTEKg Technology Co., Ltd

address: Wuhan Donghu New Technology Development Zone Huagong Science and Technology Park Modern Service Industry Base 1 R&D Building B seat 5 building

postal code: 430223

Contact Number: (+86) 027-87971689

Contact email: sales@uvledtek. com (sales)