LED UV Colorful Application | Metal Printing

We have provided mature printing solutions for numerous partners in the fields of steel tape printing, tinplate printing, and more

Compared with other packaging materials, metal packaging has many advantagesRecyclable, low migration, good protection of tank contents, beautiful appearance, and vibrant colorsetc

(1) The use of UV-LED iron printing technology can improve production efficiency

The traditional UV printing process requires preheating and cooling waiting for the on/off of the machine, while UV-LED curing equipment is not difficult to turn on even under low temperature conditions, with the light source turning on and off immediatelyProduction efficiency can be significantly improved by 10-20%.

(2) Using UV-LED printing technology is more energy-efficient and environmentally friendly

Compared with the curing method of UV lampsOnly 1/4 of the electricity consumption of the UV lamp source is neededNot only does it save energy consumption, but it also greatly reduces CO2 emissions, making it more environmentally friendly.

(3) No ozone is generated during the solidification process

UV-LED light sources do not produce short wave ultraviolet light, so they do not produce ozone during the curing process. There is no need to install odor removal devices or auxiliary devices such as exhaust ducts, which can maintain a clean working environment. This makes the U-L E D curing deviceIt can also be used in factories with dense surrounding buildings.

(4) Long service life

UV-LED light sourceThe service life can reach up to 20000 to 30000 hours which is more than ten times that of existing high-pressure mercury lamps and metal halide lamps (1500 hours), and can significantly reduce the number of light source replacements.

(5) Low heat generation

The photoelectric conversion efficiency of UV-LED light source is high, and the surface temperature of the lamp tube is only about 60 ℃, which can effectively prevent the printed matter from shrinking and deforming due to overheatingAchieve a higher setPrinting accuracy.

We have provided mature printing iron light source curing services for many partners in the fields of steel tape printing, tinplate printing, etc

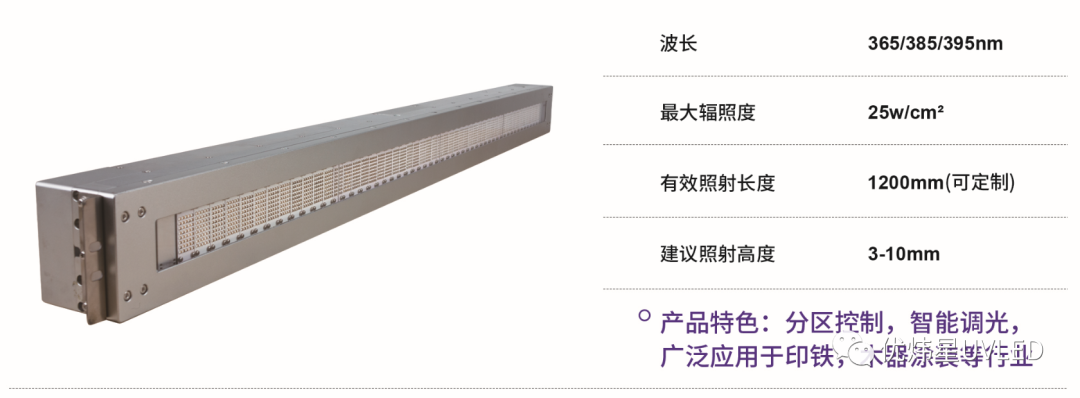

(UVLEDTEKg LED UV printing iron light source - steel tape printing)

UVLEDTEKg LED UV printed iron light source——Tinplate printing)

-March 2008-

- October 2015 -

UVLEDTEKg has started to develop fiber optic, offset printing, label, and LCD curing light source systems, implementing the "Peak Plan" of research and development, and bravely climbing the high-precision and cutting-edge field of UV curing

Strategic cooperation has been established with leading domestic UV ink suppliers to mass promote offset printing UV LED light sources. As of July 2019, more than 110 units have been installedLeading the domestic marketUV LEDOffset Printing Machine Modification Market;

The successful installation of the company's first high-power LCD curing surface light source marks the successful entry of the company's products into the LCD cell stage process, which is the first of its kind in China

The UVLEDTEKg label flexographic curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, opening the door to cooperation with well-known brand label machine manufacturers

The market of UV label, offset printing, LCD and other light source systems of UVLEDTEKg has expanded to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, and its overseas performance has achieved rapid growth

Wuhan UVLEDTEKg Technology Co., Ltd

Address: 5th Floor, Building B, R&D Building 1, Modern Service Industry Base, Huagong Science and Technology Park, Donghu New Technology Development Zone, Wuhan City

Postal Code: 430223

Contact number: (+86) 027-87971689

Contact email: sales@uvledtek.com (Sales)