What role does LED UV play in the fiber drawing process

UVLEDTEKg, escorting the diversified application of fiber optic products

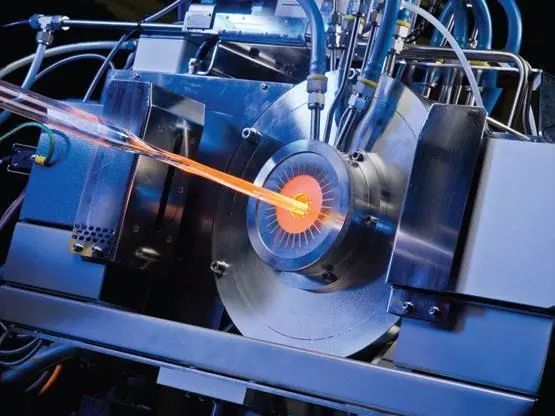

Heat the fiber preform to a soft melt state, stretch it into thin fiber bundles using gravity or external force, and then add a polymer coating on the surface of the fiber for mechanical protection

In the process of optical fiber production, in order to avoid the oxidation and adsorption of dust and moisture on the small diameter and brittle bare optical fibers that have just been drawn from the drawing furnace after contact with air, which affects the performance and effectiveness of the optical fibers, it is often necessary to apply coatings on the surface of the drawn optical fibers for protection

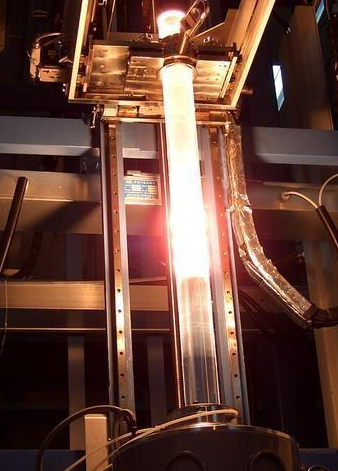

UV curing technology utilizesThe irradiation of ultraviolet light solidifies the UV curable coating applied to the surface of the optical fiberThus forming a technology with specific performance coatings

This UV curing method is characterized by itsFast curing speed, no significant solvent evaporation, excellent coating performanceExcellent performance has become the preferred method for fiber drawing and solidification

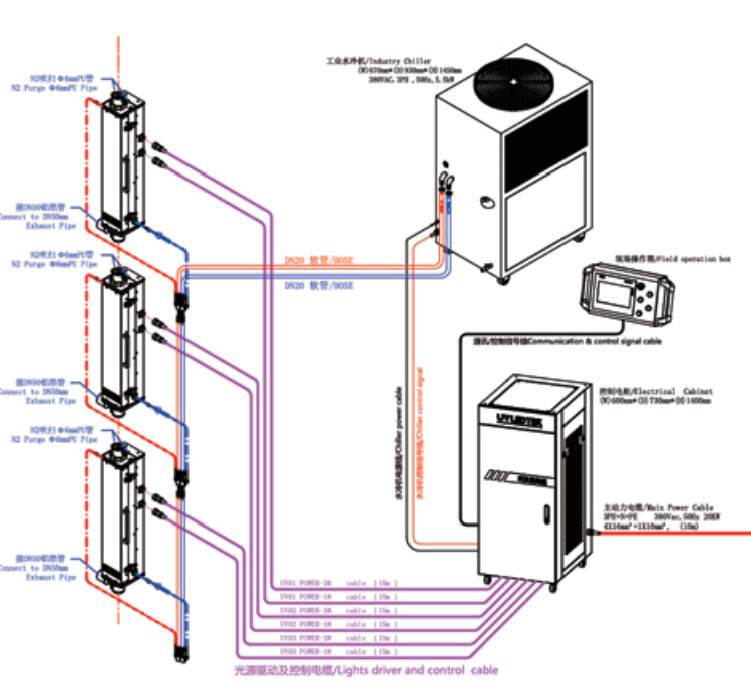

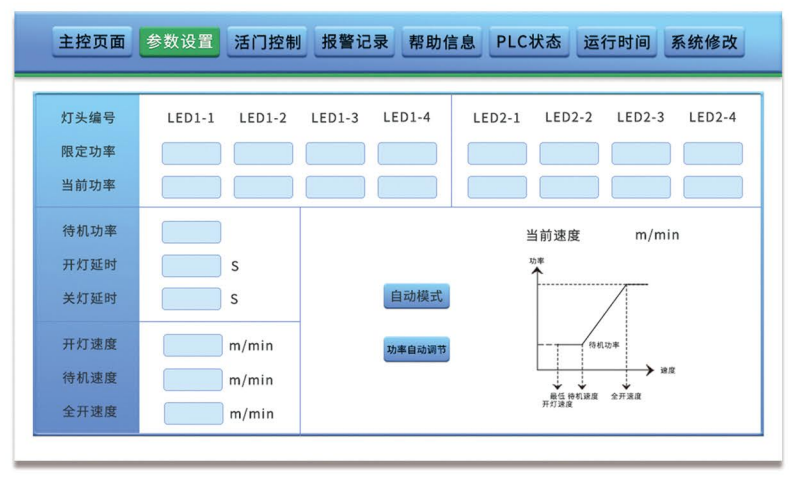

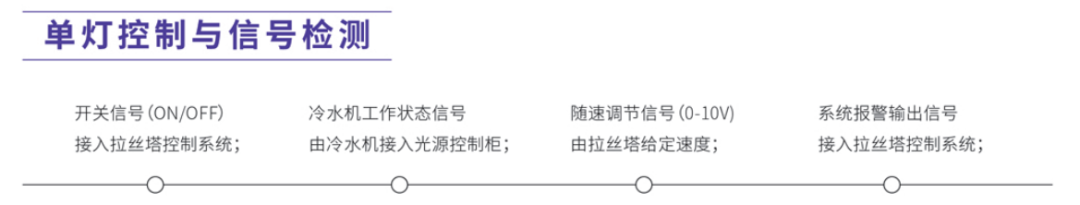

The faster the fiber drawing speed, the shorter the time it stays in the UV curing oven, which requires the fiber curing oven to achieve rapid curing of the coating with ultra-high light intensity

Peak illuminance can reach

60W/cm²

Meet the demand of fiber optic manufacturers for increased production speed

The luminous area is as long as

560mm

Improved the yield rate of fiber optic production

The degree of solidification is maintained at

About 92%

Uniform, flexible and not easily broken

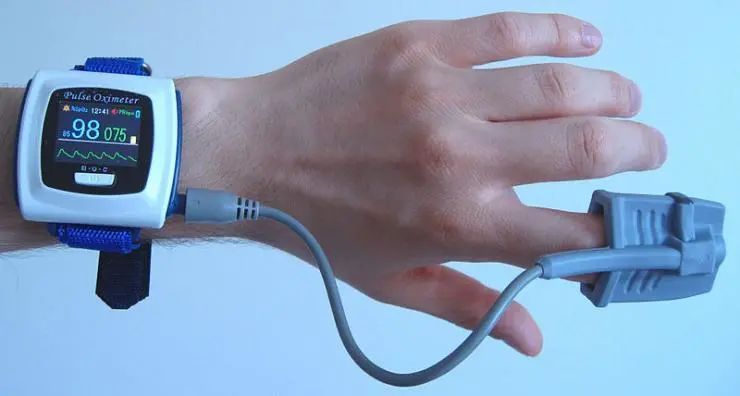

At present, optical fibers can integrate functional materials such as light, electricity, sound, heat, and piezoelectricity onto a single polymer fiber, and achieve functions such as viewing, listening, sensing, and communication on composite polymer fibers, greatly expanding the application fields of traditional optical fibers

At this time, fiber optic products can not only be used as communication tools, but also composite with materials such as optical, electrical, magnetic, thermoelectric functions, etcPreparation of multifunctional photonic or optoelectronic devices such as smart sensing devices, smart fabrics, and wearable electronic devices.

-March 2008-

- October 2015 -

UVLEDTEKg has started to develop fiber optic, offset printing, label, and LCD curing light source systems, implementing the "Peak Plan" of research and development, and bravely climbing the high-precision and cutting-edge field of UV curing

Strategic cooperation has been established with leading domestic UV ink suppliers to promote offset printing light sources in bulk. As of July 2019, more than 110 units have been installedRanked No.1 in the domestic offset printing machine modification market share;

The successful installation of the company's first high-power LCD curing surface light source marks the successful entry of the company's products into the LCD cell stage process, which is the first of its kind in China

The UVLEDTEKg label flexographic curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, opening the door to cooperation with well-known brand label machine manufacturers

The market of UV label, offset printing, LCD and other light source systems of UVLEDTEKg has expanded to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, and its overseas performance has achieved rapid growth

Wuhan UVLEDTEKg Technology Co., Ltd

Address: 5th Floor, Building B, R&D Building 1, Modern Service Industry Base, Huagong Science and Technology Park, Donghu New Technology Development Zone, Wuhan City

Postal Code: 430223

Contact number: (+86) 027-87971689

Contact email: sales@uvledtek.com (Sales)