4 Ways to Effectively Improve Offset Printing Speed

Printing speed refers to the number of prints per hour produced by a printing machine, and it is the main indicator of the printing machine's production capacity. Improving printing speed can enhance the production efficiency of printing machines and shorten production time

It refers to the printing quantity per hour of the printing machine, which is the main indicator of the printing machine's production capacity. Improving printing speed is of great significance for enhancing the production efficiency of printing machines, shortening product production cycles, and improving the efficiency of printing enterprises

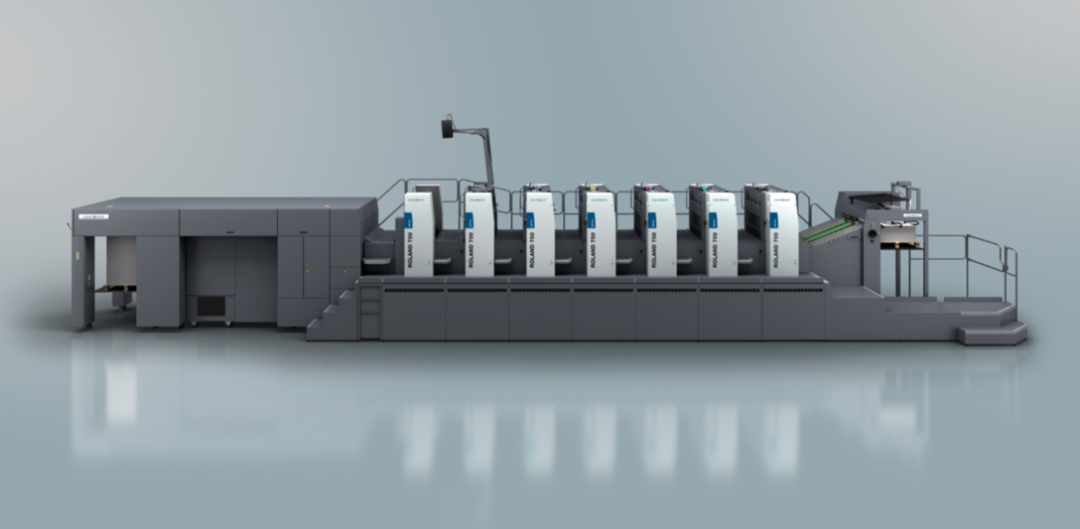

In the production process of offset printing machines, the printing speed inevitably changes from pre press preparation to trial printing, and then to formal mass printing. Only by recognizing and handling the impact of changes in printing speed on various factors such as ink, printing pressure, and printing paper, and solving them reasonably, can we ensure the reliability and stability of the printing process and effectively improve production efficiency

sun

TAI YO

ink transfer rate

Ink transfer rate is one of the factors affecting the quality of printed materials, and it decreases with increasing printing speed

Reason: The faster the printing speed, the shorter the time it takes for the ink to roll between the blanket cylinder and the impression cylinder. The position where the ink layer splits is closer to the paper, and the ink layer distributed to the paper after the ink splits becomes thinner, resulting in a decrease in ink transfer rate and a lighter ink color in the print

Method: Increase the printing pressure to increase the transfer amount of ink; While adding a release agent to the ink, increase the ink supply of the ink transfer device to thicken the ink layer transferred to the paper while maintaining the same transfer rate

Excellent

compare

RYOBI

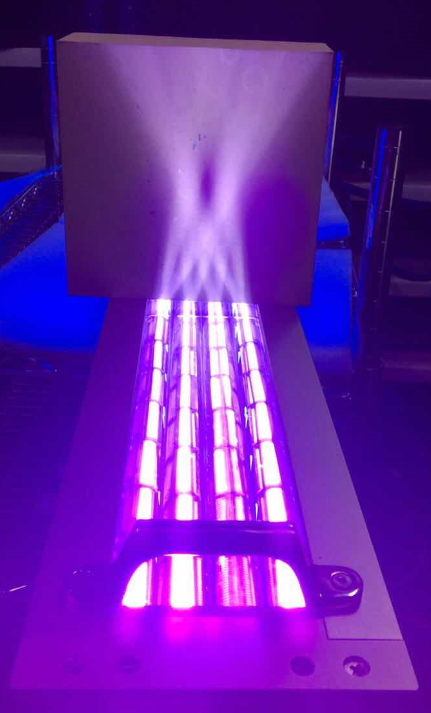

The ultraviolet light source that can instantly cure ink is particularly important in improving efficiency. Only by being able to match the ink, with a light range and power that matches the printing paper, a light intensity that matches the printing speed, and instant drying of the ink, can we meet the needs of instant printing, immediate drying, and fast delivery for offset printing orders

Method: Choose a branded light source supplier, develop an exclusive curing plan based on your actual production situation, and adjust the UV light source to the parameters that are most suitable for the manufacturer's printing speed and printing materials

virtue

fort

The embossing time of the rubber cylinder and the substrate is reduced, and the amount of ink transferred to the substrate is also reduced, resulting in a lighter ink color of the printed product

It is necessary to increase the printing pressure simultaneously to ensure sufficient contact between the printing plate and the rubber blanket, as well as between the rubber blanket and the substrate, in order to ensure smooth transfer of graphic and textual printing

pretend

light

source

Under constant pressure, the printing speed increases, the embossing time shortens, the embossing trajectory per unit time increases, the distance of paper peeling increases, and the peeling force also increases; On the contrary, as the printing speed decreases, the peeling force decreases

When the printing speed increases to a certain extent and the paper is peeled off from the blanket, due to the increased peeling force, the paper remains unchanged and the surface strength of the paper is always the same. When the peeling force is greater than the surface strength of the paper, it will inevitably lead to faults such as pulling, powdering, and even peeling of the paper

For manufacturers whose main production process is offset printing, we should take appropriate measures to adjust the parameters and energy efficiency of the four major influencing factors, in order to ensure that high-quality printed products are produced while improving printing speed and efficiency, and to strive for a larger market and user base for ourselves

-March 2008-

- October 2015 -

UVLEDTEKg has started to develop fiber optic, offset printing, label, and LCD curing light source systems, implementing the "Peak Plan" of research and development, and bravely climbing the high-precision and cutting-edge field of UV curing

Strategic cooperation has been established with leading domestic UV ink suppliers to promote offset printing light sources in bulk. As of July 2019, more than 110 units have been installedRanked No.1 in the domestic offset printing machine modification market share;

The successful installation of the company's first high-power LCD curing surface light source marks the successful entry of the company's products into the LCD cell stage process, which is the first of its kind in China

The UVLEDTEKg label flexographic curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, opening the door to cooperation with well-known brand label machine manufacturers

The market of UV label, offset printing, LCD and other light source systems of UVLEDTEKg has expanded to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, and its overseas performance has achieved rapid growth

Wuhan UVLEDTEKg Technology Co., Ltd

Address: 5th Floor, Building B, R&D Building 1, Modern Service Industry Base, Huagong Science and Technology Park, Donghu New Technology Development Zone, Wuhan City

Postal Code: 430223

Contact number: (+86) 027-87971689

Contact email: sales@uvledtek.com (Sales)