UVLEDTEK UVC LED Ultraviolet Disinfection Equipment - Leading the Innovation of Terminal Water Treatment Technology

2025-03-31

At a time when the public is paying close attention to drinking water safety, Quanzhou Huajing Innovation Technology Co., Ltd., relying on the hard-core chip technology of its holding parent company - UVLEDTEK, has used its cutting-edge UVC LED ultraviolet disinfector to build a solid line of defense for public healthy drinking water. At the just-concluded Yangtze River Water Economy Expo, Gao Chao, R&D Director of the Water Treatment and Testing Research Department of the company's Central Research Institute, was invited to give a report on "New Design of UVC LED Ultraviolet Disinfection to Promote High-Quality Drinking Water Technology Innovation". The report deeply elaborated on the innovative applications and broad prospects of UVC LED technology in the field of terminal water treatment, triggering heated discussions among experts, scholars and industry insiders attending the conference. The latest research results and practical application cases displayed by the company allowed the audience to intuitively feel the revolutionary improvement brought by innovative technologies to drinking water safety.

UV LED Drives Multiple Key Areas Forward

UV LED light sources play an indispensable role in many key areas. In the field of new energy vehicles, they help lithium batteries break through the problem of temperature resistance. In the manufacturing of 5G communication optical fibers, they increase the drawing speed and reduce costs and energy consumption. In public health and safety, they accurately disinfect bacteria and viruses. In aerospace, they are used in space stations and satellites, showing their strategic value.

Overcoming Technical Difficulties & Building Advantages in the Entire Industry Chain

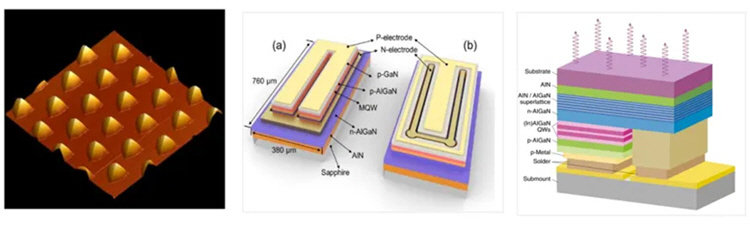

The production process of AlN/AlGaN, the core material of ultraviolet LED, has extremely strict requirements on the precision of process parameters. Even extremely slight deviations may change the crystal structure of the material, thus significantly affecting its optoelectronic performance. After ten years of research, Wuhan UVLEDTEK has built up R&D and manufacturing capabilities for the entire industry chain, breaking the technological blockade and achieving independent control.

Deeply Cultivate the Field of Water Treatment - Precise Sterilization to Ensure Water Safety

UVC LED has shown broad application prospects in the field of water treatment. From water plants to drinking water at each water supply terminal and to sewage treatment after discharge, from food and beverage, animal husbandry to sterile water in the production of medicines and semiconductor processes, from household drinking water to safe water in public areas such as restaurants, beverage shops and amusement parks, from industrial cooling circulating water sterilization to public swimming pool disinfection, we need effective and safe water disinfection equipment everywhere.

Compared with traditional chemical disinfection such as chlorination and ozone, UVC LED has significant advantages. It is a physical disinfection, does not change the properties of water, eliminates secondary pollution of water by chemical substances, and does not produce any disinfection by-products that affect the human body and health. It has rapid sterilization and can instantly inactivate all pathogenic bacteria within a certain dose. It can also degrade chlorine-containing organic matter and eliminate the hazards of combined chlorine. It is safe to operate and has no risks in the transportation and preparation of drugs. It is a veritable new green environmental protection technology.

| Disinfection Method | Advantages | Disadvantages |

| Chlorine Disinfection | 1. High degree of inactivation of bacteria and viruses 2. Continuous disinfection capability |

1. The safety risk is very high (liquid chlorine and chlorine dioxide disinfection). 2. Chemical disinfection produces nearly a thousand chlorine disinfection by-products. Produces gene mutations and carcinogenic trihalomethanes. 3. Poor ability to kill chlorine-resistant bacteria such as two insects and avian mycobacteria. |

| Ozone Disinfection | 1. Thorough sterilization, no residue, broad-spectrum sterilization; 2. It is a globally recognized green, broad-spectrum and efficient disinfectant. |

1. Complex process. 2. High cost. 3. Excessive use will produce carcinogenic byproducts such as bromate |

| Ultraviolet Disinfection | 1. Physical disinfection, no secondary pollution. 2. Short contact time, fast sterilization speed. 3. Ultraviolet disinfection is non-selective disinfection, which can quickly inactivate ammonia-resistant bacteria. 4. It can degrade chlorine-containing organic matter and eliminate the impact of combined chlorine on the human body. 5. The operation is safe and reliable, without the safety risks of drug transportation and preparation. |

No sustained sterilization capability |

Compared with traditional UV light source mercury lamp, UV-LED is non-toxic and environmentally friendly, has low power, long life, fast opening, and compact structure. UVC LED technology has significant advantages in energy consumption, maintenance cost and disinfection effect, and can bring higher economic benefits and sustainable environmental benefits to water supply systems.

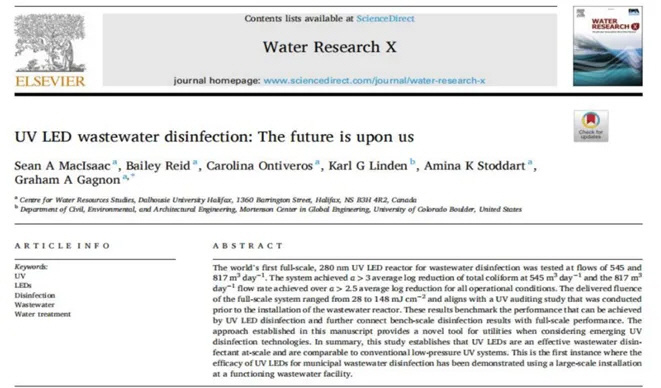

Internationally, TYPHON in the UK has built the world's first municipal-scale UV LED drinking water disinfection system, with a treatment capacity of up to 28MLD (5136GPM). The system uses advanced UVC LED technology, and through precise light field design and flow field optimization, the killing effect on Cryptosporidium reaches 4 LRV Crypto (22mJ/cm²). Norwegian water companies are also actively turning to UVC LED technology and gradually phasing out traditional mercury lamps. More and more water supply and sewage treatment application cases are being piloted in old developed countries such as the United States and the European Union, and are gradually being promoted on a large scale.

In China, Quanzhou Water Group and Youweixin Technology have joined hands to make this technology a key research and development project and have assembled a group of domestic experts in related fields to overcome difficulties. In June 2024, they successfully developed the first set of large-flow UVC LED disinfection equipment in China, which passed various challenges and test reports at one time, with a sterilization rate of up to 99.999%, and has been implemented in the secondary water supply system. At the same time, the full system of products for the secondary water supply industry and terminal direct drinking water applications have also been developed a few days ago, and all batches of products are in pilot applications. This indicates that this technology will break the technology monopoly. We have realized independent intellectual property rights from the core chip end to the overall application development of the equipment and software system integration, and have the ability to mass produce. This will greatly enhance the safety of terminal water supply and is an important technological innovation and alternative application breakthrough in the field of terminal water supply disinfection.

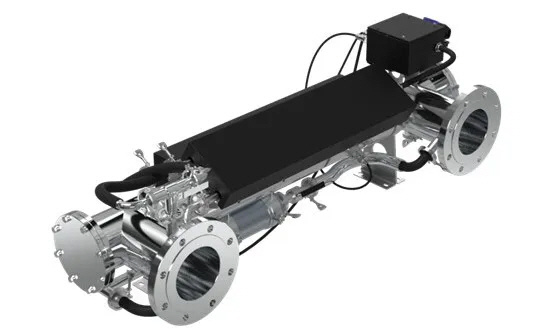

Excellent Product Design & High Performance in All Aspects

1. High optical power chips and high optical density light sources

In terms of material growth, UVLEDTEK uses pyramid nano-patterned substrates and high-speed pulse epitaxial growth healing technology to produce high-quality AlGaN epitaxial materials. In terms of chip electrode metal system optimization, the unique high-reflectivity electrode structure and SWDL reflection structure play a key role, ultimately increasing the device's luminous efficiency by more than 32%. In addition, the material research and development team carefully designed the component gradient quantum well structure and the gradient component electron blocking layer, starting from the principles of semiconductor physics, to adjust the band structure, improve the current injection efficiency, enhance the electron-hole recombination efficiency, and make the optical power output stronger.

2. Breakthrough of the UV wavelength of traditional mercury lamps to improve efficiency

The UV LED based on AlGaN materials developed by UVLEDTEK can continuously adjust the emission wavelength in the range of 210-365nm, breaking through the wavelength limit of 254nm of traditional mercury lamps. International studies have shown that the 279nm wavelength is more effective in inactivating MS2 than the 254nm wavelength, and the water penetration effect is better than 254nm in the 260-280nm wavelength range. At the same time, for SS and bacterial flocs of the same size, the larger the wavelength, the smaller the shielding effect. This means that under the same killing rate requirements, the UVC LED requires a smaller dose, which effectively improves the disinfection energy efficiency and can achieve accurate and rapid sterilization.

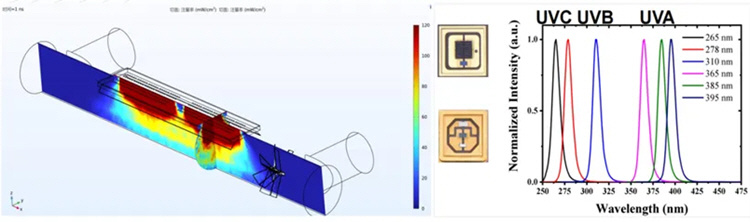

3. Light field design without UV shadow area, sterilization without dead angle

Through advanced geometric optical design, and using multi-media penetration simulation and multi-physics field numerical simulation technology, ultraviolet light is accurately injected into the reaction chamber, and a high-efficiency ultraviolet radiation area without shadow area is constructed in the cavity. This innovative design ensures that every corner of the water body can receive sufficient ultraviolet radiation during the disinfection process, achieving all-round and dead-angle sterilization, and effectively avoiding the sterilization blind area caused by uneven light field.

4. Flow field design with rotating guide device to optimize flow state and improve effect

After in-depth research on the flow state of water bodies, the system R&D team found that the maximum flow rate has a significant impact on the sterilization effect. From the principle of fluid mechanics, high-speed flowing water may cause microorganisms to stay too short in the ultraviolet irradiation area and fail to fully receive ultraviolet irradiation, thereby reducing the sterilization effect. Our team successfully reduced the maximum flow rate by cleverly changing the entrance and exit postures to rotate the water through the irradiation area. This design not only improves the sterilization effect, but also makes the water absorb the ultraviolet radiation dose more evenly. The rotating water flow can fully expose the microorganisms in the water to ultraviolet rays, ensuring that each microorganism can receive enough sterilization doses, thereby significantly improving the overall sterilization efficiency.

5. Pipe water light source cooling technology, efficient heat dissipation

Our high-power LED UV sterilizer adopts advanced water cooling method, directly using the water in the pipeline to dissipate heat from the light source, without the need for additional special equipment, which greatly saves investment costs. At the same time, this technology has the characteristics of small size and high efficiency. Through the AI control algorithm, the light intensity and cooling water volume can be adjusted in real time according to the changes in the processing volume. For example, when the processing volume increases, the light intensity is automatically increased and the cooling water volume is increased to ensure the stable operation of the light source; when the processing volume decreases, the light intensity and cooling water volume are correspondingly reduced to achieve energy saving and consumption reduction. In addition, the quartz light window is consistent with the water temperature, which effectively slows down the scaling problem (the surface temperature of traditional mercury lamps is as high as 600-1000 degrees, which is easy to scale), and it is easy to maintain. The light source can be disassembled and maintained without stopping the water or switching the pipeline. Through monitoring of the actual operating equipment, it was found that the service life of the light source can be extended by 30%-50% after adopting this cooling technology.

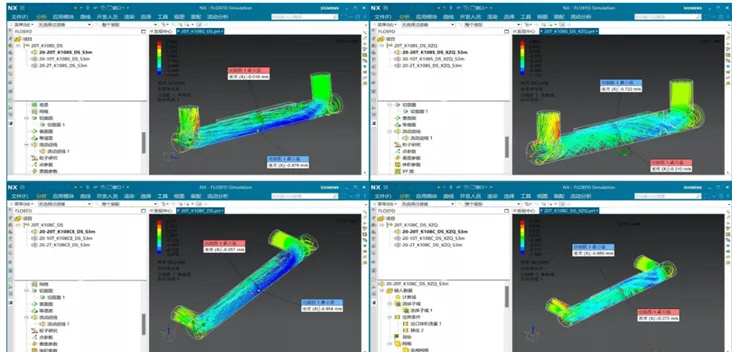

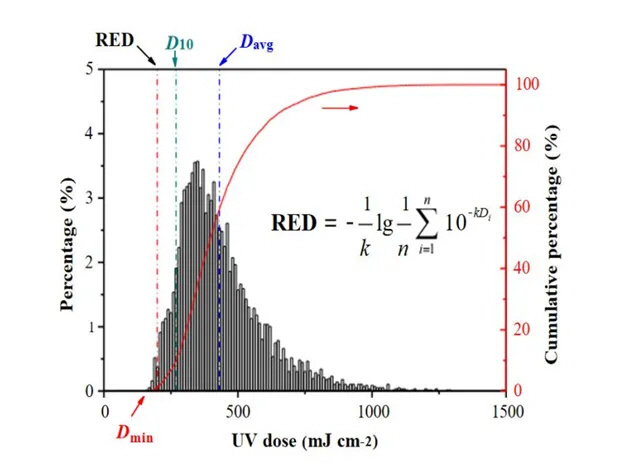

6. RED-CFD coupling simulation for precise quantification and reliable operation

The technical team adopts the internationally leading RED-CFD design of UVC LED reactor. In this design, the light source does not need to be immersed in the water body through a sleeve, which makes the flow state more reasonable and easier to achieve the coupling of the light field and the flow field. The high-reflection design further increases the efficiency of UV light. The DC power supply does not require a high-frequency ballast and can be directly connected to the photovoltaic power supply to achieve efficient use of energy. At the same time, the design has a smaller head loss (compared to the larger head loss caused by the traditional mercury lamp support plate, etc.), the whole machine is small in size, and the required installation space is small. Through RED-CFD coupling simulation analysis, the core parameters of the equipment such as ultraviolet sterilization dose, light source configuration, and water flow rate can be accurately quantified to ensure excellent product performance and reliable operation, providing users with stable and efficient disinfection solutions.

7. Simple and clear human-machine interface, easy to operate

The human-machine interface of the UVC LED sterilizer for secondary water supply is simple and clear. Through the interactive interface, the operator can intuitively and clearly understand the main operating parameters of the equipment, such as the current dosage, light intensity, and flow rate. At the same time, the device log, alarm information, etc. can be easily viewed through the menu, and the operation process is simple and easy to understand. This simple and clear interactive design reduces the learning cost of operators, improves the operation and maintenance efficiency of the equipment, and makes equipment management more convenient and efficient.

8. Modular design, simple maintenance and operation, guaranteed operation

The UVC LED ultraviolet disinfector for secondary water supply adopts a modular design concept, and the light source and the reaction chamber are independent of each other. Ultraviolet light is evenly injected into the water body through the high-transmittance quartz glass on the reaction chamber. Under the premise of ensuring uninterrupted water supply, the light source can be easily maintained and serviced. The modular design makes the maintenance of the equipment more convenient. When a module fails, it can be quickly replaced to ensure the continuous and stable operation of the equipment and provide users with a reliable user experience.

9. Quick response and stable operation, energy saving and environmental protection, cost reduction

UVC LED ultraviolet disinfection device starts quickly and can reach peak power instantly without preheating (traditional mercury lamps take 15-30 minutes to preheat, and the light intensity rises slowly). Its light intensity output is not affected by water temperature, and the light intensity adjustment range is wide, up to 0-100% (traditional mercury lamps are only 30-100%). The start and stop operation of the equipment will not damage the life (traditional mercury lamps frequently start and stop and their life is rapidly reduced), and it can be linked with flow, residual chlorine, and UVT to accurately adapt to different working conditions.

After strict testing by a professional third-party organization, the disinfection and sterilization effect of our UVC LED ultraviolet sterilizer meets and exceeds the national standard requirements, providing a solid and reliable guarantee for the terminal secondary supply and quality-differentiated water supply system. As an important development direction for solving drinking water safety and health problems in the future, quality-differentiated water supply is of great significance, especially in areas with scarce water resources. The UV-LED ultraviolet sterilizer is undoubtedly the best choice for terminal water safety disinfection with its excellent performance.

At present, the product has been piloted in Fujian, Zhejiang, Wuhan, Ezhou, Suzhou and other regions in China. We look forward to more knowledgeable people who are interested in the application of this technology to work with us to promote the promotion and popularization of this product and related technical research, and continue to work hard for terminal drinking water safety.

Ensure terminal water safety and protect people's drinking water health. Let us work together to protect the safety of every drop of drinking water with the power of science and technology, move towards a new era of high-quality drinking water, build a solid line of defense for the health of our family, and enjoy a beautiful and healthy life.

2025 /

03-31

Classification:

Exhibition Information

Related Information