"core" wisdom, new life|look UVLED Integrate into various industries

UV LED Compared to traditional light sources UV mercury lamp, More environmentally friendly, Efficient and energy-efficient, It is a truly sustainable green industrial technology, In many applications

Compared to traditional UV mercury lamp, More environmentally friendly, Efficient and energy-efficient, It is a truly sustainable green industrial technology, It has gradually replaced traditional mercury lamp light sources in many application fields.

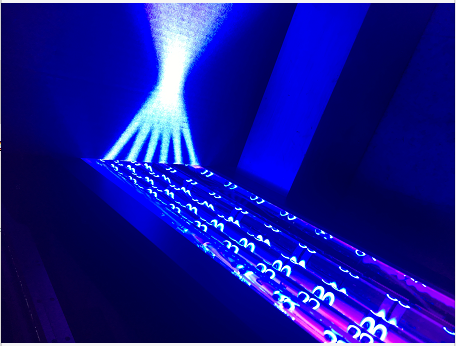

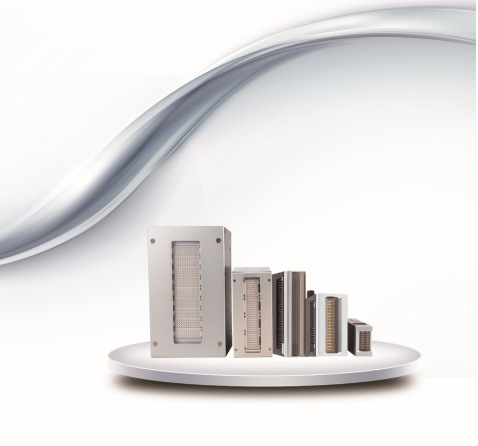

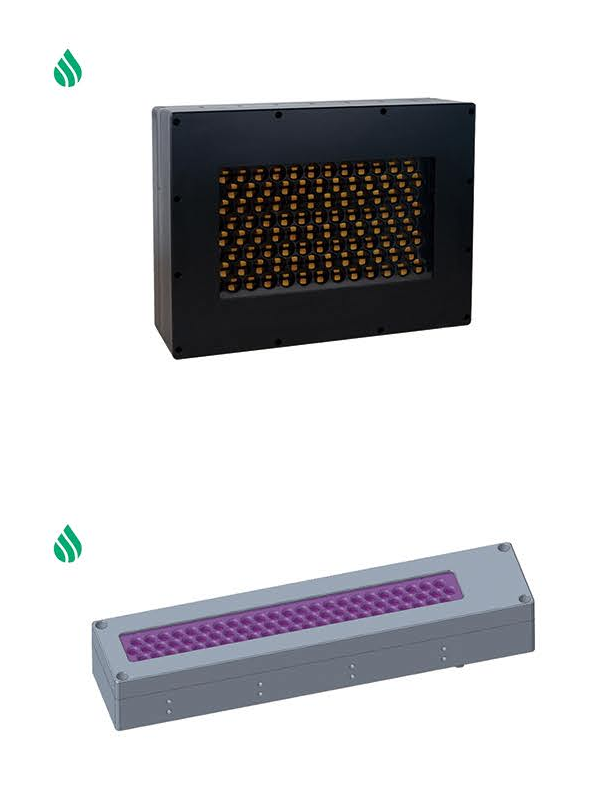

(Youwei Star UV LED Telephoto offset printing light source)

UV LED Can directly convert electrical energy into UV light, And it emits single band ultraviolet light, The energy of light is highly concentrated in a specific ultraviolet band, And traditional UV The emission spectrum of mercury lamps is very wide, The ultraviolet spectral range that truly plays an effective curing role only accounts for a part of it, Low photoelectric conversion efficiency, High energy consumption.

Traditional mercury lamps produce infrared radiation, And emit a large amount of heat, Easy to cause damage to heat sensitive substrates. But UV LED For cold light sources, Can effectively prevent the substrate from shrinking and deforming due to overheating, More adaptability to materials. At the same time, no ozone will be generated during the solidification process, Being able to maintain a good working environment, Compared to traditional mercury lamps, it is safer, more environmentally friendly.

UV LED No need to preheat like a mercury lamp, There is no need to keep the lamp tube constantly on in order to maintain its lifespan and work efficiency. UV LED Instantly switchable light, The output energy can also be freely set, And it can automatically adjust according to the machine speed, Very energy-efficient, Simple and convenient control.

UV LED The service life of the lamp is longer than that of traditional mercury lamps 10 More than double, And the light decays very slowly, The service life is not affected by the number of switches. Almost no maintenance required, Reduced maintenance costs.

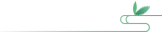

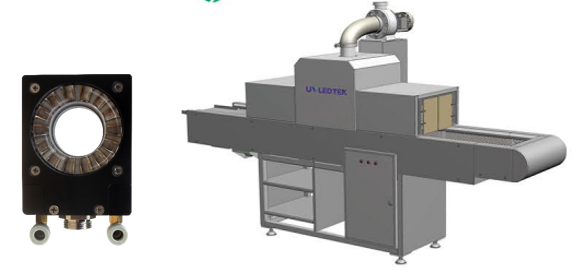

LED Small size of light source equipment, The irradiation device and related supporting devices are very compact, No need for the previous large mechanical installation space and pipeline construction, Capable of adapting to various production processes, The production process is also more efficient.

UV LED Advantages of inkjet printing:

energy saving, efficient, high resolution, adaptMultiple substrates

Application field:

Industrial or decorative printing, large formatink jet, Label and packaging printing

LED UV Offset printing and regular printing UV Compared to printing

Throughout the entire printing production process, More energy-efficient and environmentally friendly, long lifespan

Can reduceGundam 70~80%Energy consumption

And it has outstanding performance in printing materialsadaptability

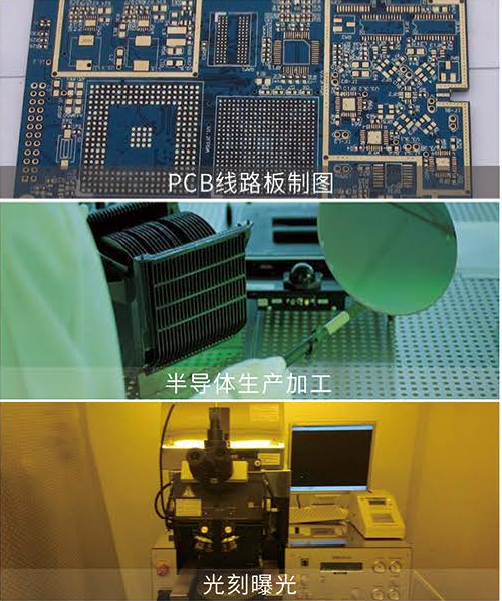

component (capacitance, inductance, Various plugins, screw, chip wait) fixed

Moisture proof sealing and core circuit, Chip protection, oxidation resistant coatingprotect

Circuit board type protection (corner) coating

ground wire, flying wire, Coil fixation

Wave soldering through-holemask

Compared to traditional painting methods

UV LED Not rightMoisture content of substrateexert an influence

And fromClosed bottom, primer, color correction, topcoat

realize UV LED Rapid curing construction technology

Eliminating the traditional wooden base, topcoatLong dryDrying and solidification time

andMulti channel spraying constructionThe complicated process

Can achieveMechanization of the entire line, Assembly line operation

For the factoryImprovement of production capacityHas greatfacilitation

use UV LED Curing glue has many advantages

for exampleLow heat release, Lower energy demand

Save curing time and location, Improve productivity, easierautomation

Therefore, it is widely usedMicroelectronics industryandmedical deviceIn the field

play a role inbonding, fixed, protectWaiting for action

LED advantage:

cold light source, less pollution, Fast solidification, Low energy consumption, Film-forming propertyCan be superior

Application field:

mobile phone, Automotive Coatings, optical lens, plastic coating, optical fibercoating

The active production and life have created a rich and colorful environment uvled application

use "core" wisdom Create a new life

Serve with heart, Quality first

- 2008 year 03 moon -

- 2015 year 10 moon -

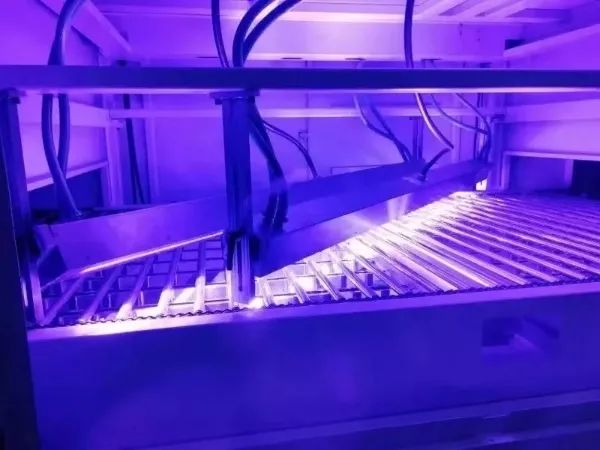

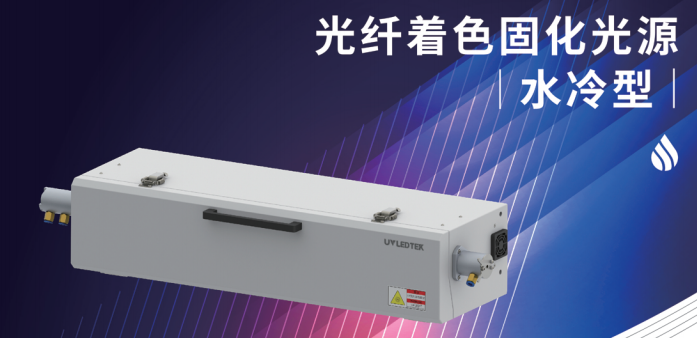

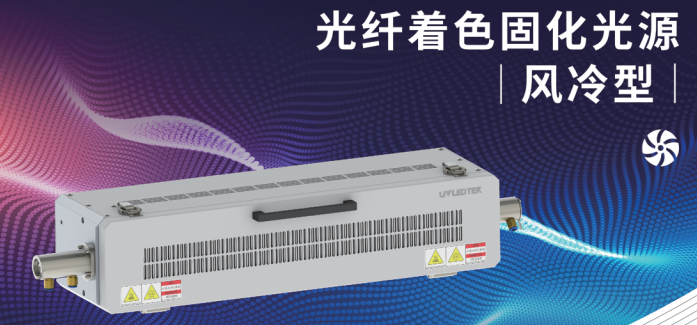

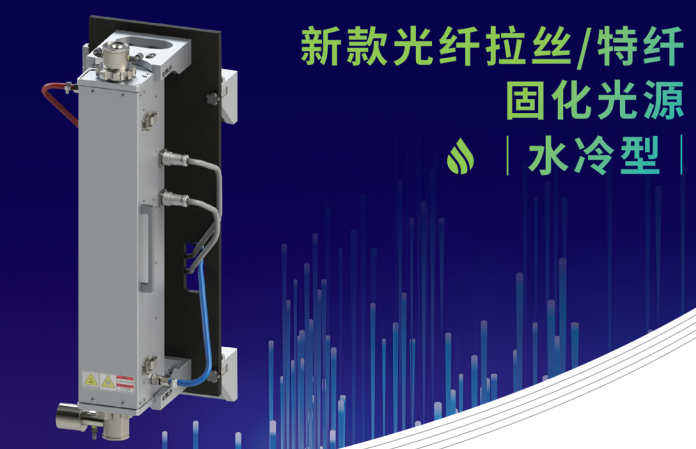

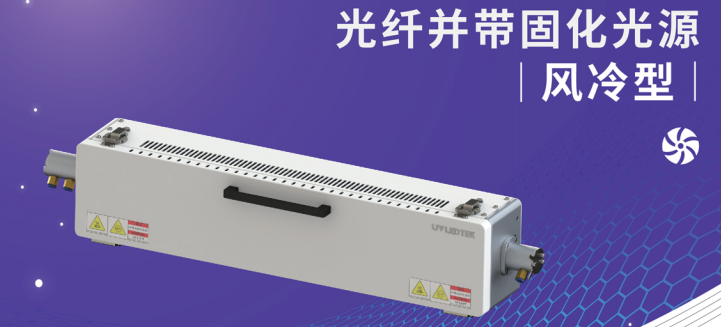

UVLEDTEKg begins to develop optical fibers, Offset printing, label, Liquid Crystal Curing Light Source System, Implementing research and development "Peak Climbing Plan" , Brave Climbing UV High precision and cutting-edge fields of solidification;

Compared to domestic UV Leading ink supplier reaches strategic partnership, Batch promotion of offset printing light sources, as of 2019 year 7 Installed monthly 110 Above the stage, Market share of domestic offset printing machine modification NO. 1;

The company's first high-power LCD curing surface light source was successfully installed in one go, Mark the successful entry of the company's products LCD cell Duan Craft, For the first time in China;

UVLEDTEKg label flexographic printing curing light source system breaks through the industry's highest printing speed bottleneck with exclusive process technology, Open the door to cooperation with well-known brand label machine manufacturers;

Youwei Star UV label, Offset printing, Expansion of LCD and other light source system markets to Europe, Japan, Thailand, Malaysia, Türkiye, Vietnam, Brazil and other countries, Rapid growth in overseas performance.

Wuhan UVLEDTEKg Technology Co., Ltd

address: Wuhan Donghu New Technology Development Zone Huagong Science and Technology Park Modern Service Industry Base 1 R&D Building B seat 5 building

postal code: 430223

Contact Number: (+86) 027-87971689

Contact email: sales@uvledtek. com (sales)